ANNEALING OF THERMOPLASTICS – WHAT IS IT, WHY DO IT?

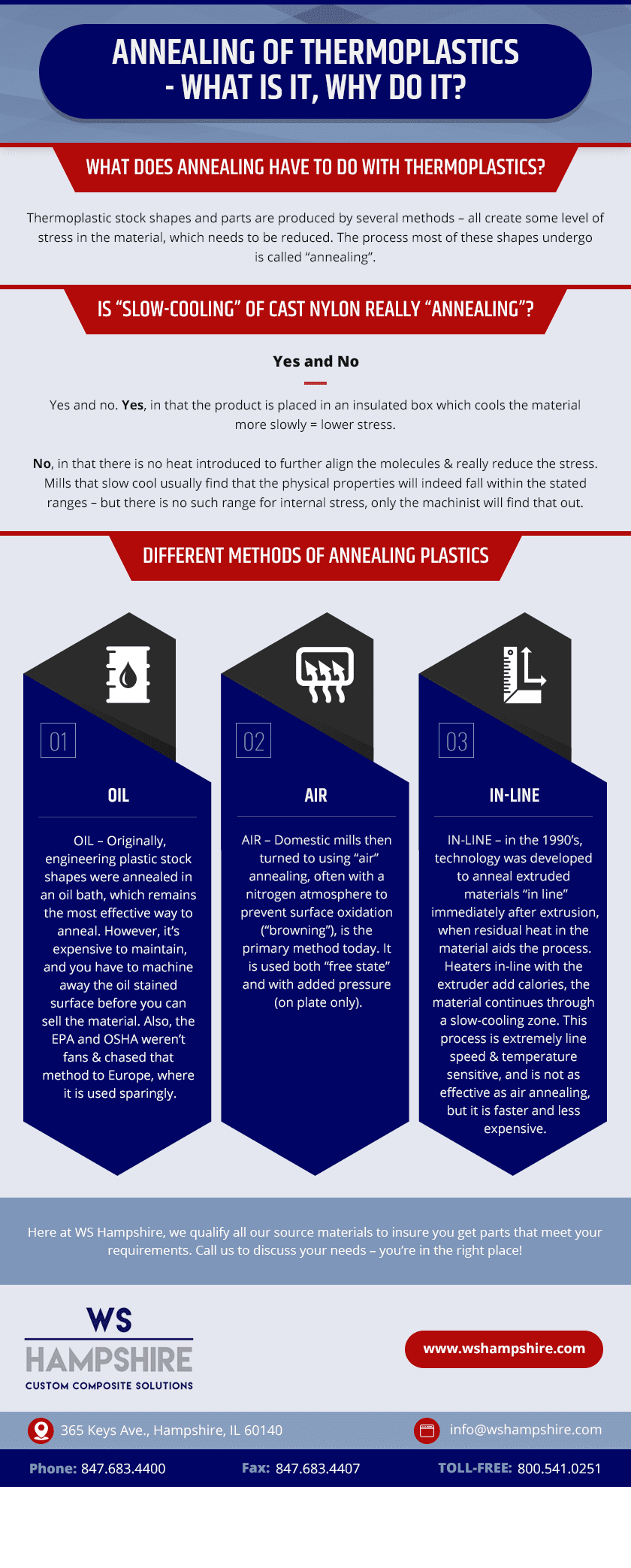

Thermoplastic stock shapes and parts are produced by several methods – all create some level of stress in the material, which needs to be reduced for several reasons. The process most of these shapes undergo is called “annealing”.

The process is straightforward but isn’t “easy”. You heat the material to a temperature below its glass transition point, hold it there for time that is dependent on the material and thickness, then cool it. Both the heating and cooling must be done slowly, or the material will be thermally shocked which can cause, instability (rather than stability).

In plastics, extruded and injection molded shapes have the highest process-induced internal stress and require extensive annealing. Before cast nylon was available in FDA natural, companies would use extruded 101 (6/6) nylon rod up to 6” in diameter, and it wasn’t unusual even for thoroughly annealed 6” rod to explode every so often when contacted by a tool.

Compression molding is usually used to produce materials that cannot be melted – most often PTFE (“Teflon®”) based material, and UHMW-PE. These materials are “fused” under pressure and heat, similar to powder metallurgy. Despite this lower stress process, thick sections still require some extra attention to relieve stress.

Other materials are cast – several nylons, urethanes are examples. You pour the different base materials, and they react to become that material in the mold. With nylon, again, heavier sections require special handling. And, with cast nylon, secondary annealing also bakes off the residual unreacted monomer, which attracts excess moisture, and makes the nylon ma harder.

Occasionally, when machining parts that have unique designs – deep pockets, large cross-section differences – it’s appropriate to “rough” machine the part, reanneal it, then finish machine to print.

Is “slow-cooling” of cast nylon really “annealing”? – yes and no. Yes, in that the product is placed in an insulated box which cools the material more slowly = lower stress. No, in that there is no heat introduced to further align the molecules & really reduce the stress. Mills that slow cool usually find that the physical properties will indeed fall within the stated ranges – but there is no such range for internal stress, only the machinist will find that out.

Are there different methods of annealing plastics? Yes.

- OIL – Originally, engineering plastic stock shapes were annealed in an oil bath, which remains the most effective way to anneal. However, it’s expensive to maintain, and you have to machine away the oil stained surface before you can sell the material. Also, the EPA and OSHA weren’t fans & chased that method to Europe, where it is used sparingly.

- AIR – Domestic mills then turned to using “air” annealing, often with a nitrogen atmosphere to prevent surface oxidation (“browning”), is the primary method today. It is used both “free state” and with added pressure (on plate only).

- “IN-LINE” – in the 1990’s, technology was developed to anneal extruded materials “in line” immediately after extrusion, when residual heat in the material aids the process. Heaters in-line with the extruder add calories, the material continues through a slow-cooling zone. This process is extremely line speed & temperature sensitive, and is not as effective as air annealing, but it is faster and less expensive.

Here at WS Hampshire, we qualify all our source materials to insure you get parts that meet your requirements. Call us to discuss your needs – you’re in the right place!

Tom Connelly is a self f proclaimed “Street Engineer” with over 40 years in the plastics industry.