Compare Sheet Only:

Compare Tube Only:

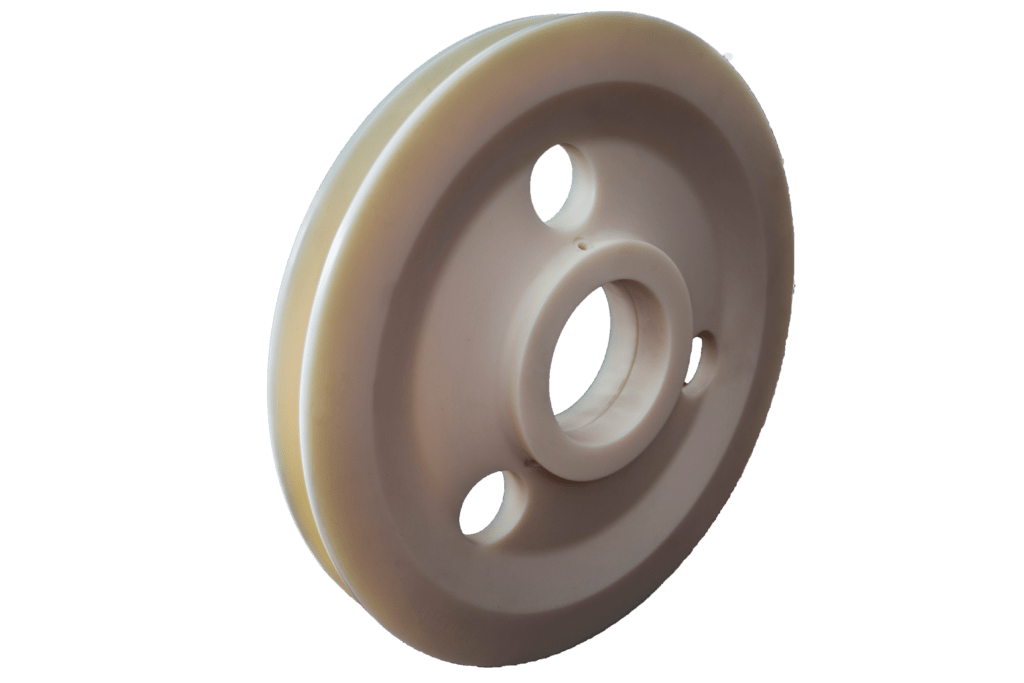

QUALITY CAST NYLON SHEAVES FROM WS HAMPSHIRE

WS Hampshire is a full-line custom fabricator and supplier of non-metallic materials, including Timco Technical Plastics and Ryertex Phenolics. Equipped with years of industry experience and a 135,000-square-foot manufacturing facility, our team has the knowledge and tools to produce standard or custom sheaves to meet virtually any heavy equipment application.

Sheaves Applications

WS Hampshire fabricates many types of sheaves for applications in the heavy equipment industry. One of these settings is floating and shipboard cranes, where sheaves must withstand harsh marine environments. Sheaves also run conveyors on material processing equipment. In addition, fire trucks utilize our sheaves for rescue pulley systems.

Here are some other applications of sheaves:

- Aerospace: landing gear, elevators, rudders, ailerons, spoilers, flaps

- Marine: steering systems, marine dredges, fisheries, custom marine equipment

- Medical: extrusion equipment, scopes, surgical robots, surgical tables, recovery beds, strand annealing furnaces, wire drawing equipment, traction equipment

- Commercial: lifting, rigging, overhead doors, transportation, towing, winching, overhead lighting, safety systems

Advantages of Using Nylon Sheaves

Industrial nylon sheaves offer many benefits, especially compared to metal sheaves:

- Lightweight construction: Compared to metal sheaves, nylon sheaves are much lighter, reducing the overall weight of the system without compromising durability.

- Longer cable/rope life: Nylon sheaves are more elastic and allow a larger contact surface area between the groove and the rope or cable, distributing the load more evenly and reducing stress. As a result, the entire system benefits from reduced maintenance and cost savings.

- Reduced operating costs: Because nylon sheaves last longer than metal sheaves, they do not need to be replaced as often. Facility managers can also order lubricated grades of nylon sheaves, eliminating the need to purchase and apply lubrication separately.

- Increased system load capacity: Nylon sheaves weigh about 20% that of metal sheaves, so the lifting system can use the weight savings to lift more, especially with boom point sheave applications.

- Corrosion resistance: Unlike metal, nylon is a chemically resistant material that will not rust or corrode.

Nylon Sheaves at WS Hampshire

Nylon sheaves are strong, durable, and reliable in heavy-duty lifting operations. WS Hampshire custom-fabricates nylon sheaves, replacing traditional metal sheaves. Since the 1890s, WS Hampshire has been providing custom nonmetal solutions with our CNC machining, stamping, punching, vacuum forming, rotary die, and assembly services. Today we specialize in replacing conventional materials with ones that are a better fit for their application, saving our customers time and money.

Note that nylon sheaves do have special storage recommendations in order to retain dimensional stability.

To learn more about our OEM products and capabilities, request more information or contact us today.

Nylon Sheaves for Heavy Equipment Industry

In the heavy equipment industry, sheaves play an important role in lifting systems.

The grooved wheel components are used alongside ropes, cables, or chains in pulley systems to change both the direction and amount of force employed to facilitate the lifting and lowering of materials and equipment.

Traditionally, sheaves have been made from cast iron or steel. However, the introduction of high-performance plastics and more advanced plastic manufacturing methods have led to the adoption of cast nylon as a suitable construction material alternative. Compared to their cast iron and steel counterparts, cast nylon sheaves offer a number of advantages and find application in a variety of mechanical equipment and systems, such as cranes, forklifts, and wire drawing and cable stranding machines.

Following the acquisition of Timco, Inc. in 2017, the team at WS Hampshire is proud to offer customers cast nylon sheaves in various designs and sizes to suit a wide range of heavy equipment applications. We have assembly capabilities and can supply your custom designed sheave with your specified components such as sleeves, bearings, magnetic sensor inserts, and snap rings.

BENEFITS OF TIMCO CAST NYLON SHEAVES

- Benefits

In comparison to cast iron and steel sheaves, Timco cast nylon sheaves to provide several benefits when used in pulley systems, including:

- Lower component weight. Cast nylon sheaves are one-seventh the weight of steel sheaves of similar design. In larger lifting equipment and systems, this quality can result in weight savings of up to 2,200 pounds. By reducing the weight of a material handling system, industry professionals can increase operational efficiency, reduce the amount of load and stress experienced, and facilitate handling and operation.

- Longer service life for wire rope. In material handling systems, the rope or wire cable bears the most stress. Metal sheaves, being harder than wore rope, flattens the rope and accelerates wear on the rope. The resiliency and elasticity of Timco cast nylon sheaves, allowing the groove to deform slightly then rebound, reduce the amount of stress on the wire rope, thereby extending its service life by up to 300% compared to the rope life expectancy over hard metal sheaves.

- Improved safety. The lighter weight of nylon components allow for easier installation and reduced likelihood of injury to maintenance personnel.

- Greater corrosion and weather resistance. Corrosion significantly affects the amount of friction in material handling systems, resulting in more wear and stress. Cast nylon sheaves are rust, chemical, and saltwater corrosion resistant, making them the ideal solution for lifting systems used in marine and other harsh environments.

- Longer pulley system service lives. Cast nylon sheaves can also dampen system vibration, resulting in less wear in other system components such as bearings, shafts, and housings. Less wear means components last longer, resulting in lower maintenance and replacement costs and downtime requirements, all of which translate to more profit.

- Better durability and longevity. Besides extending the useful life of other system components, cast nylon sheaves also outlast their metallic counterparts.