Compare Sheet Only:

Compare Tube Only:

Plastics are synthetic or semi-synthetic polymer and other composite materials containing plasticizers, stabilizers, fillers, and other additives that enhance their processing and performance characteristics. The exact formulation of a plastic determines the properties it exhibits, with each plastic formula typically resulting in distinct qualities that make it suitable for specific use cases.

WS Hampshire, Inc. is a full-service fabricator and supplier of non-metallic materials, including plastics. Our 135,000-square foot facility allows us to stock and process a wide range of plastic materials for use in industrial and commercial applications, including the following:

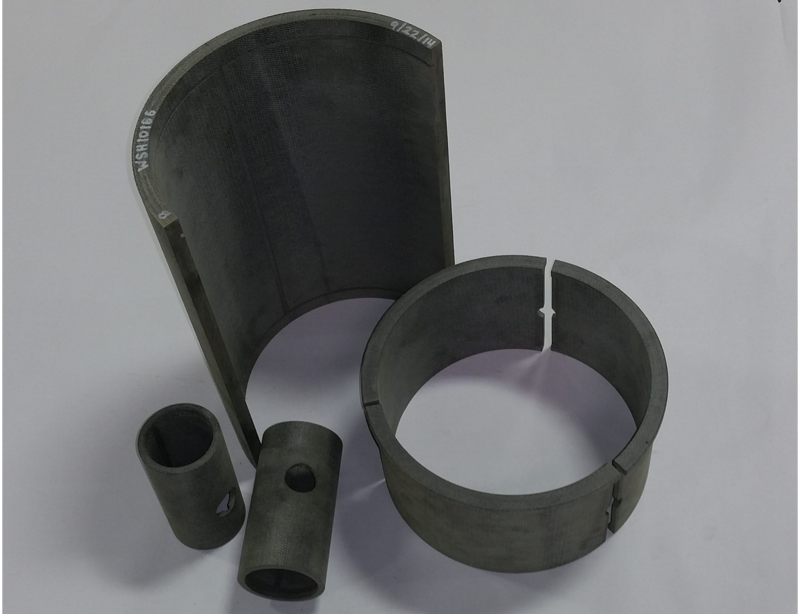

THERMOSET LAMINATES

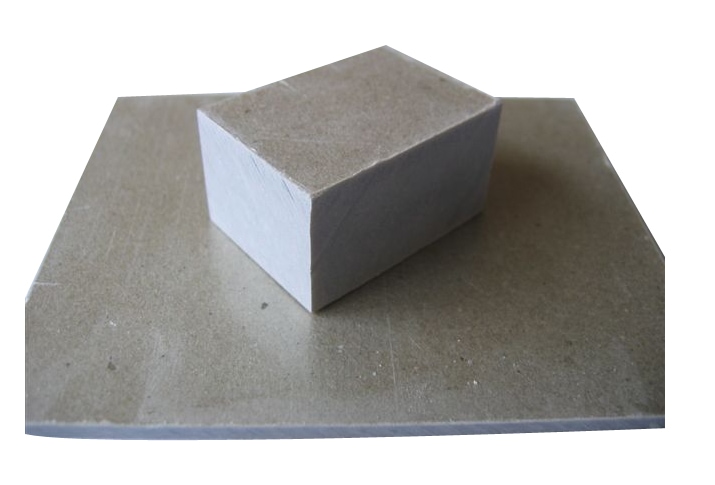

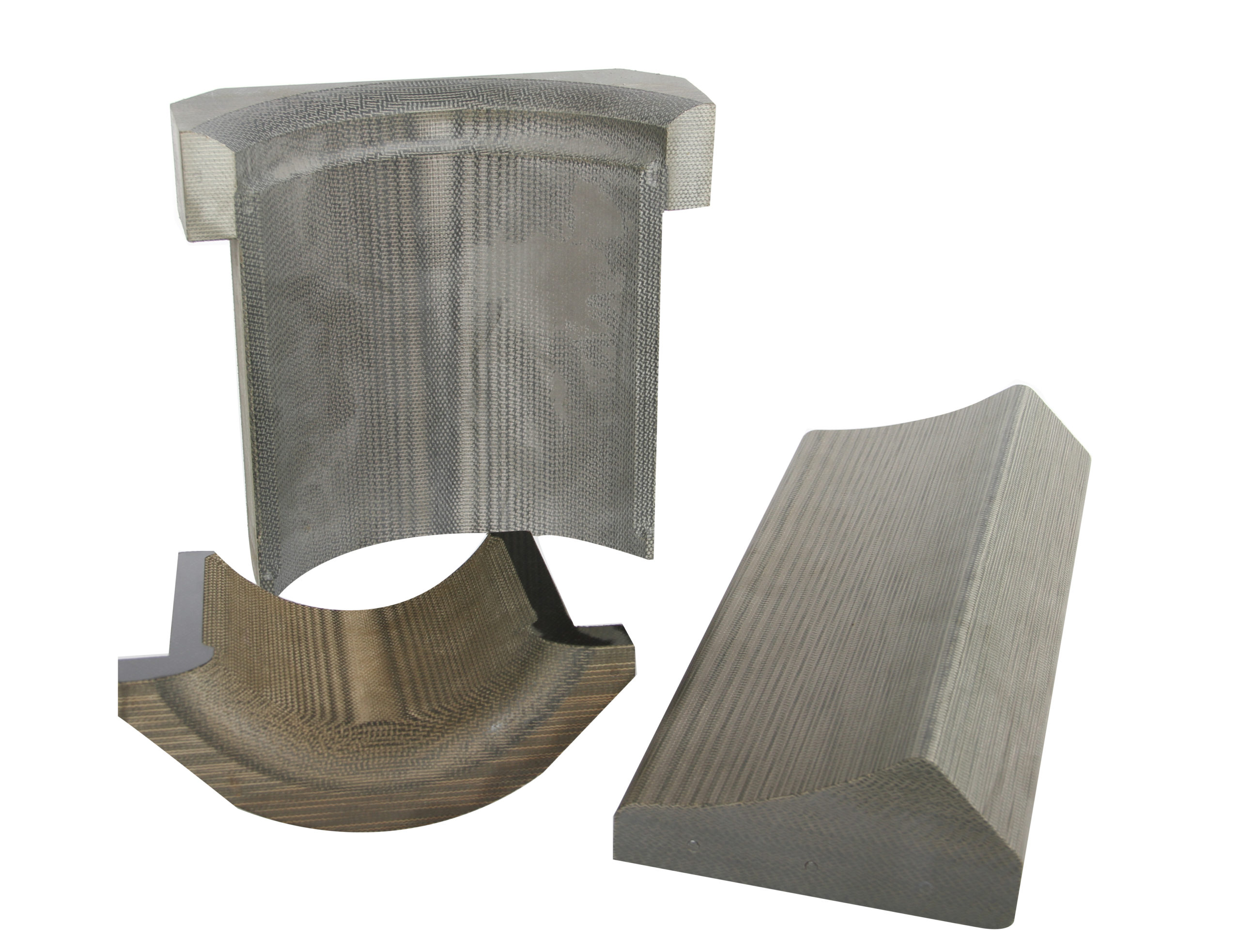

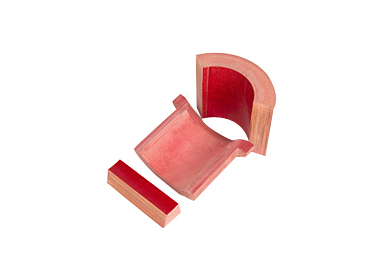

Phenolic plastics—also referred to as industrial laminates—consist of alternating layers of resin and material, all of which are exposed to high heat and pressure to form a solid plastic form. Depending on the type of phenolic plastic, the resin employed can be epoxies, melamines, polyesters, or silicones, and the material can be cloth, glass-based fabric, or paper. These composite materials are available in many forms, including sheet and convolute wound tube, and find use in a wide range of industrial applications, due to their machinability, corrosion resistance, and electrical insulation properties.

At WS Hampshire, we offer the following phenolic plastics:

Ryertex®. Ryertex® is a high-performance thermoset laminate composite material often used as an alternative to metal for industrial and commercial applications involving high heat, load, and/or speed. It can withstand temperatures of 250° F to 572° F. We offer availability in 16 grades for specific applications:

- Ryertex C

Ryertex C

Ryertex® C – Canvas is one of the most popular phenolic laminate grades used around the world and is often referred to by the name “Micarta®“. Strong and durable with outstanding compressive strength and good machinability, this composite provides excellent wear and abrasion resistance with a low coefficient of friction.

- Ryertex CE

Ryertex CE

Grade CE – Canvas/Electrical is one of the most popular phenolic laminate grades used around the world and is often referred to by the generic name “Micarta®“. Strong and durable with outstanding compressive strength and good machinability, this composite provides excellent wear and abrasion resistance with a low coefficient of friction. This electrical grade offers enhanced electrical properties when compared to grade C.

- Ryertex CG

Ryertex CG

Ryertex® CG – Canvas/Graphite is a medium weave cotton fabric (Ryertex® C) combined with a phenolic resin system containing carbon graphite as a solid lubricant.

This phenolic laminate is used where a low coefficient of friction is the primary need allowing for improved wear life of the parts. Graphite is impregnated into the construction of the material and acts as a lubricant. It transfers to the metal surface providing lubrication on both surfaces. Ryertex® CG composite laminate can be run with or without additional lubrication.

- Ryertex 223 Marine

Ryertex® 223 (Grade C, Marine Grade)

Ryertex® 223 – Marine Grade provides the same strength and durability as Ryertex® C phenolic laminate with outstanding compressive strength and good machinability. This composite is made with a modified resin system that offers less water absorption which makes this grade ideal for all types of marine bearings or in submerged applications.

- Ryertex G3

Ryertex G3

Ryertex® PG (NEMA G3) is an industrial laminate comprised of a woven glass fabric impregnated with phenolic resin. This composite possesses high compressive, flexural, and impact strength with the ability to withstand higher temperatures than canvas based phenolics. G3 also offers low moisture absorption and high dimensional stability.

- Ryertex G5

- Ryertex G7

Ryertex G7

Grade G7 – Ryertex® G7 is made with a specially blended, high temperature phenolic resin with a woven glass fabric substrate.

This composite creates a product that provides excellent electrical properties along with impressive flexural, compressive and impact strengths at temperatures up to 160 ºC.

Grade G7 thermoset laminates are used in heavy duty industrial applications for bearings, bushings and wear parts.

- Ryertex G9

- Ryertex Grades G10 And FR4

Ryertex Grades G10 And FR4

Ryertex® G10 – Epoxy Fiberglass is a high performance epoxy glass laminate. It has outstanding mechanical properties that exceed nearly all other thermoset composites. It is a Class B electrical insulator at temperatures to 325°F and water absorption is extremely low.

Ryertex® FR4 – Flame Retardant Epoxy Fiberglass bromine is added to the G10 resin system to give the material flame retardant properties.

- Ryertex G11

- Ryertex HD/A

Ryertex HD/A

Ryertex® HDA – Heavy Duty Canvas with Alumina is a phenolic laminate composite that consists of multiple plies of heavy weight canvas saturated with phenolic resin and modified with alumina that adds hardness to the material resulting in increased wear resistance.

Ryertex® HDA provides superior load-bearing properties and has a coefficient of thermal expansion that closely matches metal shafts. It has exceptional impact resistance making it ideal for high load, high demand applications.

- Ryertex HD/M

- Ryertex L

- Ryertex LE

Ryertex LE

Ryertex® LE – Linen/Electrical Grade is a finely woven, 4 oz/sqft cotton based phenolic with 40% higher tensile strength than Ryertex® CE. This composite is great for smaller electrical parts requiring intricate machining as the design helps to hold tighter tolerances when manufacturing. Ryertex® LE is rated as a Class A insulator and has very low moisture absorption.

- Ryertex S/T

Trespa®. Trespa is a high-pressure laminate plate of fibers or Kraft paper. It is coated with phenolic resin for use as interior or exterior cladding and decorative surfaces. We provide the following types:

- TopLab® Plus

- TopLab® Base

- TopLab® Vertical

- Virtuon® Sheet

Virtuon® Sheet

Developed for demanding interior applications, Trespa’s underlying technology combines wood-based fibers with thermosetting resins under high pressure and at high temperatures, transforming them into robust composite panels that meet the most exacting specifications. The unique properties of Trespa® Virtuon® make them highly durable with a long life of retained appearance.

Arboron® sheet. Arboron® is a paper-based composite filled with a phenolic thermosetting resin and topped with an outer layer of melamine. The sheets are uniform and have good resistance to abrasion, chemicals, and electrical creep.

Resiten® sheet. Resiten® is a paper-grade laminate that manufacturers often use for laser engraved signage, applications that carry electrical voltage, and more. We offer these sheets in a wide range of grades, sizes, and thicknesses.

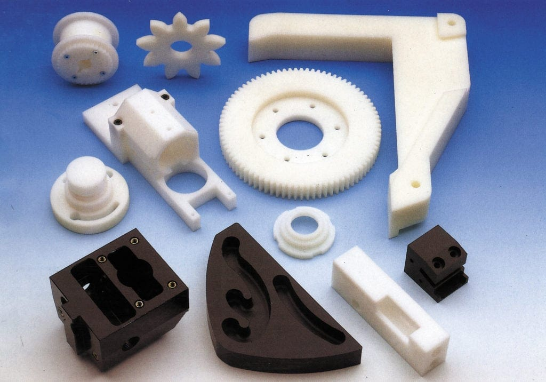

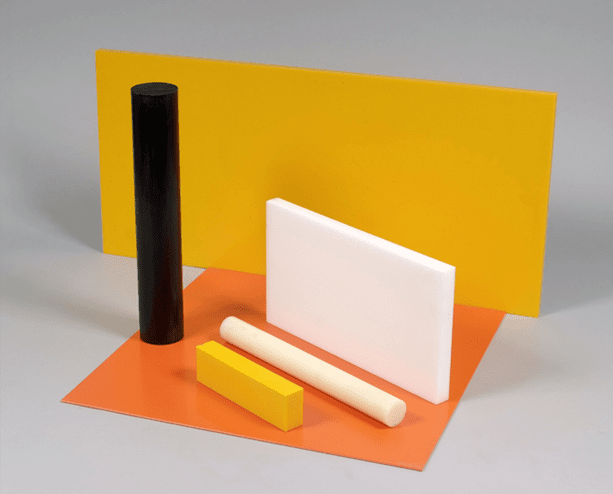

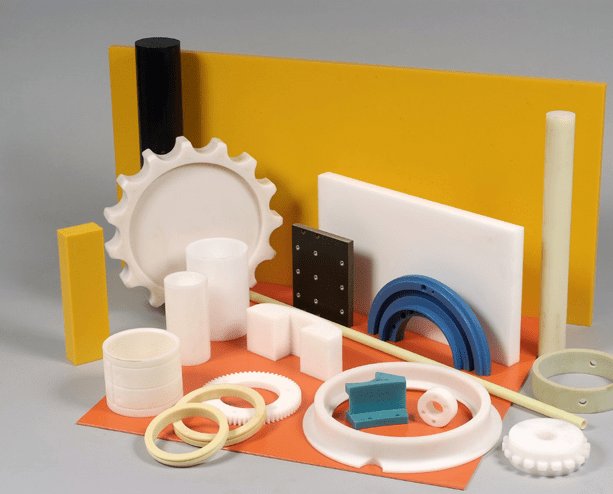

THERMOPLASTICS

Thermoplastics are plastic composite materials that become soft and pliable when exposed to sufficiently high temperatures. In contrast to thermosets, they can be melted, formed, and recycled several times over.

At WS Hampshire, we offer the following thermoplastics:

- Acrylonitrile Butadiene Styrene (ABS)

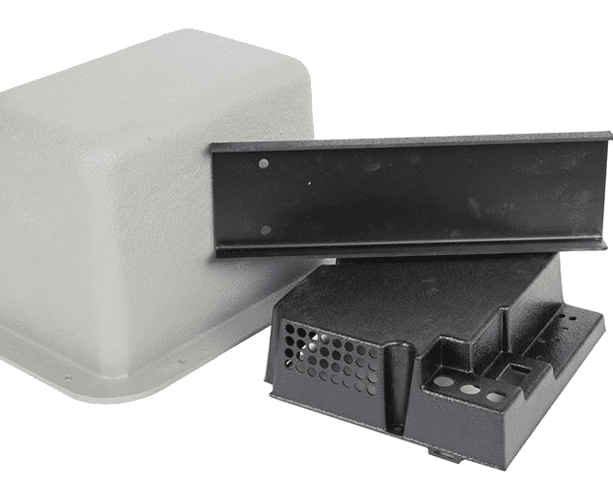

Acrylonitrile-Butadiene-Styrene (ABS).

ABS plastic is a tough, rigid thermoplastic that is produced both as an extruded and annealed product. Annealed ABS has excellent impact, abrasion, moisture, electrical and creep resistance properties with very good chemical and stress-cracking resistance. It is resistant to inorganic salt solutions, alkalis and many acids. Extruded ABS is excellent for vacuum and thermoforming applications.

- Acetal

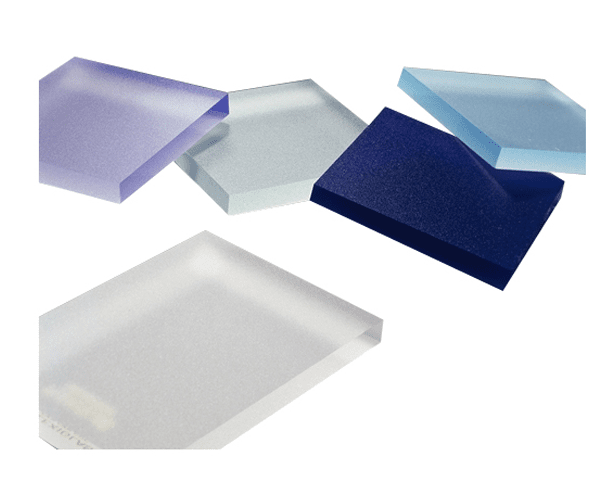

- Acrylic

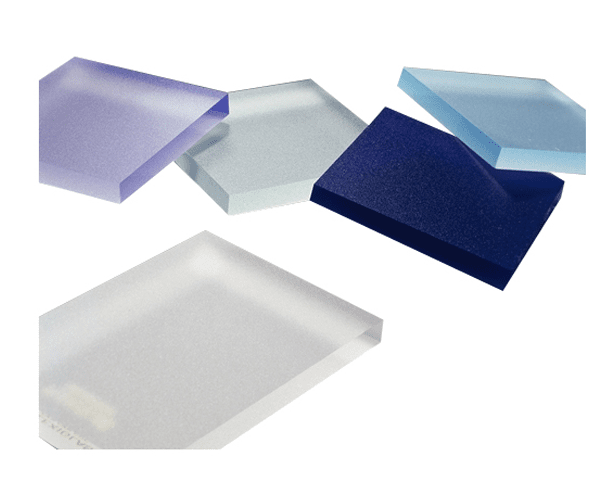

Acrylic

Acrylic offers crystal-clear transparency combined with outstanding chemical resistance, outdoor weatherability, and dimensional stability. It is also strong, resistant to breaking, easy to machine, has a low water absorption rate and resists staining by human handling. Acrylic is offered in cast and extruded forms.

- High-Density Polyethylene

- High-Impact Polystyrene

High-Impact Polystyrene

HIPS is produced from the toughest resins to provide a superior product mix of processability, stiffness, formability, and impact strength. It is formulated to provide excellent toughness while being a very low cost thermoplastic. It will meet a wide variety of applications as it is extremely versatile and easily fabricated by drilling, routing, sawing, die cutting, or thermoforming.

- Low-Density Polyethylene

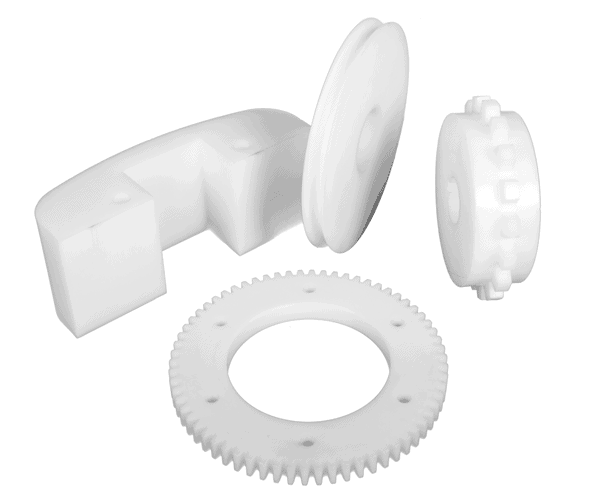

- Nylon

Nylon

Nylon is a versatile and popular engineering plastic with outstanding hardness and tensile strength, plus superior wear resistance. A low coefficient of friction is another advantage along with heat resistance as high as 230 degrees Fahrenheit in some grades. Nylon is an excellent choice for parts that aren’t in frequent contact with strong acids, organic solvents, or sunlight. The addition of oil, glass, or moly disulfide improves the properties listed above to provide even better wear and abrasion resistance.

- Polyethylene Terephthalate

Polyethylene Terephthalate

A preferred replacement for Acetal where there is a concern for dimensional stability after machining. P.E.T. has excellent wear resistance and a low coefficient of friction, in addition to a very low water absorption rate and being FDA compliant. The low moisture characteristic makes P.E.T. ideal for electrical applications. The outstanding hardness and stiffness properties along with good chemical resistance enables P.E.T. to be the answer to many applications.

- Polycarbonate

Polycarbonate

Polycarbonate is the toughest transparent plastic produced. Outstanding impact strength (it is virtually unbreakable) makes it the material of choice for many industrial applications. It has good electrical insulation properties and low moisture absorption. Polycarbonate is resistant to both heat and flame, and is dimensionally stable and generally unaffected by greases, oils, and acids. Weatherability is good, but slightly below that of acrylic. Ultraviolet rays cause slight discoloring and embrittlement. Polycarbonate tubing offers the advantages of a clear, see-through tubing with the added impact toughness necessary for industrial applications.

- PTFE

Polytetrafluoroethylene

PTFE is a tough mechanical thermoplastic that has an extremely low coefficient of friction along with a 500 degree Fahrenheit temperature rating offering good mechanical properties, making it an excellent choice for a variety of applications requiring a low coefficient of friction.

- Ultra-High Molecular Weight Polyethylene

Ultra-High Molecular Weight Polyethylene

UHMW is an exceptionally tough plastic that holds up, even after repeated impact. The abrasion resistance is extraordinary, with low friction under load. Virgin Grade UHMW is also exceptionally resistant to chemical attack including organic solvents. It’s easily machined, self-lubricating and absorbs almost no water while providing high dielectric strength, but only moderate compression strength. UHMW operates safely at 160 ºF and doesn’t break under IZOD impact testing.

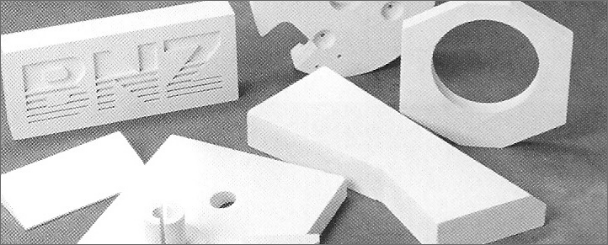

THERMAL INSULATION

Thermally insulative composite materials can absorb and disrupt the transfer of heat energy from one object to another. Thermal insulating materials can protect complex configurations from heat buildup and excessive heat from electrical malfunctions.

- CS85

- Glastherm

- Marinite®

Marinite®

Marinite® C, A, I, M, and P are non-asbestos calcium silicate structural insulators that combine high strength and excellent thermal insulating characteristics for heat processing, fire protection, and electrical resistance applications.

Marinite® A, and Marinite® C are heat treated formulations ideal for conveying, containing, and forming molten aluminum and other non-ferrous alloys. Marinite® P, Marinite® I, and Marinite® M are oven dried formulations designed for various machined parts, fire protection, and heat insulating processes. The ideal fireproof insulation board for your application depends on the specific balance of insulation and strength that you require.

- Mica

- Transite®

Transite®

Transite® cement boards are engineered to handle higher temperatures, increased loads, and greater electrical conditions with less shrinkage and degradation than other asbestos-free formulas. Busbar supports, press plates, foundry core plates, and arc shields are some of the applications for this heat resistant insulation board.

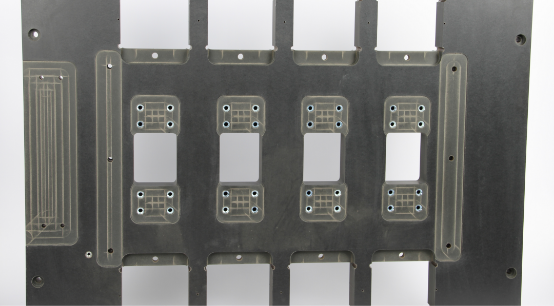

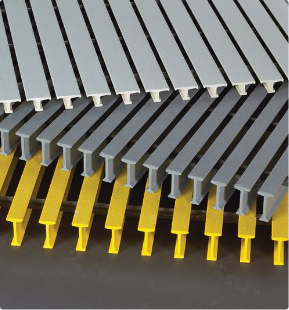

FIBERGLASS-REINFORCED PLASTIC (FRP) MATERIALS

Fiberglass-reinforced plastics are composite materials that have been reinforced with glass fibers. They can offer strength comparable to that of metal and flexibility comparable to that of carbon fiber. These qualities, combined with their resistance to water damage, make them suitable for heavy-duty applications that are outdoors or regularly exposed to water.

At WS Hampshire, we offer the following fiberglass-reinforced plastic materials:

Extren™

Extren is a low-maintenance material available in a variety of forms, including rounds, square/rectangles, tubes, and beams.

GPO

GPO is a thermoset polyester sheet reinforced with fiberglass and filler material suitable for use as an electrical insulator. It is available in three grades: GPO-1, GPO-2, and GPO-3.

Wesliner

Wesliner is a thermoset composite sheet material that has excellent chemical, physical, and thermal resistance. It’s also UL certified with a flame spread of 25.

ELECTRICAL INSULATION

Electrical insulators are materials with high electrical resistivity, meaning they resist the flow of electrical charges. When used alongside electrical conductors, this quality makes them ideal for use as protection against electricity-related issues, such as electrocution, short-circuiting and arcing.

At WS Hampshire, we offer the following electrical insulation materials:

- Mylar®

- Dacron Mylar Dacron

- Nomex®

- GPO

- Mica

- Kraft Paper

Kraft Paper

Kraft Paper consists of virgin wood pulp. There are no adhesives or chemical additives making Kraft Paper ideal for electrical applications.

Kraft Laminates have good temperature capabilities with improved dielectric strength, and very good mechanical properties as a result of the polyester film laminates. The laminate provides excellent cut-through resistance, good stiffness with improved resistance to tearing.

- Cequin

Cequin

CeQuin 3M™ CeQUIN I and II Inorganic Insulating Papers have high inorganic content and are comprised of glass fibers, microfibers, and inorganic fillers with less than 10% organic binder content. It performs to temperature up to 250 ºC while UL systems recognized to Class 220(R) and CSA Component approved. CeQUIN possess excellent thermal conductivity, good varnish absorption, good retained dielectric and low moisture absorption.

- COPACO

COPACO

COPACO electrical insulating papers are produced from high-grade new denim cuttings providing excellent aging properties. This paper has high tensile, tear, burst and dielectric properties. It possesses a smooth surface that improves insertion into slot cells, and provides good abrasion resistance.

- Tufquin™

Tufquin™

3M TufQUI™ 110 Hybrid Insulating Paper is a flexible, conformable paper which has physical toughness in the form of high tensile strength and excellent tear resistance. TufQUI™ 110 paper offers good dielectric characteristics and thermal conductivity in conjunction with high temperature performance.

3M TufQUI™ 120 Hybrid Insulating Paper is generically the same as TufQUIN™ 110 paper, with the exception that TufQUI™ 120 paper is created through a modified manufacturing process that yields thicker constructions while maintaining conformability.