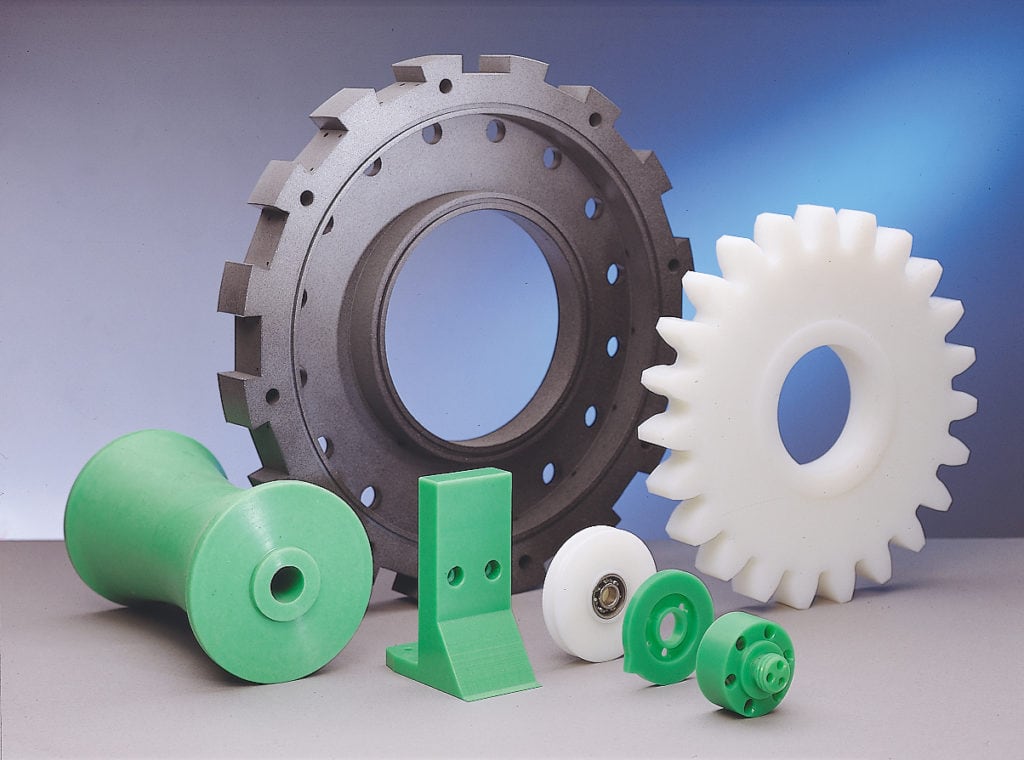

We are proud to be the premier fabricator of Timco Technical Plastic components to the manufacturers of oil & gas exploration equipment. Plastics have proven themselves as ideal for many highly demanding applications found in the off-shore industry. Our fabricated sheaves and other wear and structural components offer many benefits to the off-shore industry including reduced downtime and cost. Our products can reduce component weight and eliminate lubrication requirements while also resisting saltwater and other chemical attacks. Examples include nylon ball valve seats, seals made from PTFE or PEEK, and high temperature or high corrosion bearing and wear applications. Some materials can also offer performance to temperatures of up to 500° F and innovative solutions like replaceable cable-saving grooves for large sheaves are routinely provided by our team. Our team will work with you to identify the application conditions as well as design and load requirements of your part in order to help to select the correct material so that parts function in your application.

Our Parts Offer:

- Performance in Harsh Environments Including Sea Water

- Corrosion Resistance

- Low Water Absorption

- Long Part Life

- Weight Reduction

- Reduced Maintenance Costs

- Lower Cost in Use

- Ability to Run Without Lubrication

- Reduced Noise

- Reduced Wear on Mating Parts

Parts WS Hampshire Supplies:

- Wire Rope Sheaves

- Hot Stab Plug for Well Heads

- Thread Protectors

- Pipe Centralizers

- Wear Plates and Slide Pads

- Bearings, Bushings

- Manifolds

- Seals

- Valve Seats

- Wear Rings

- Other Pump Components

- V-rollers

- Seals, Connectors and Insulators in Down-Hole Equipment