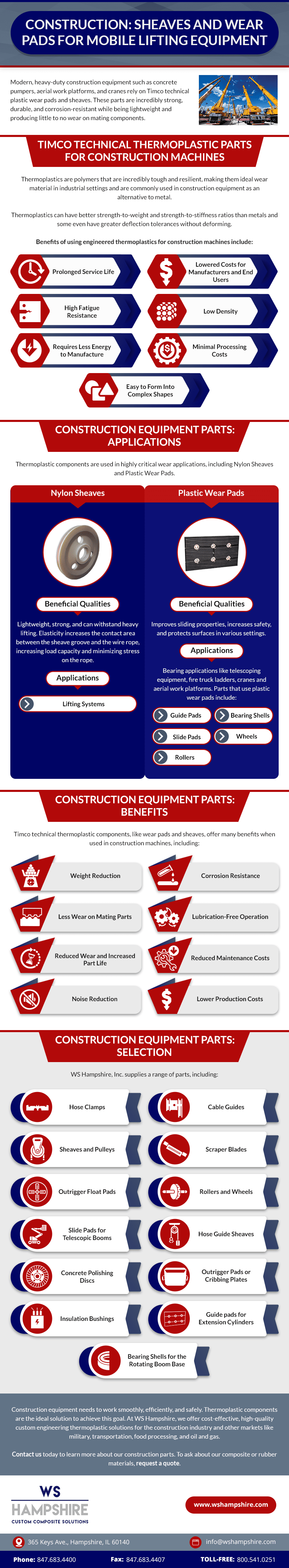

Timco Technical Thermoplastic Parts for Construction Machines

WS Hampshire acquired Timco, Inc. in 2017. Timco provides engineering plastics that reduce the weight and maintenance demands of industrial equipment. We take pride in continuing Timco’s reputation of providing material handling, construction, and rolling mill equipment. Today, WS Hampshire is the largest supplier of nonmetallic machined sheaves in North America.

Thermoplastics are polymers that are incredibly tough and resilient, making them ideal wear material in industrial settings and are commonly used in construction equipment as an alternative to metal. Thermoplastics can have better strength-to-weight and strength-to-stiffness ratios than metals and some even have greater deflection tolerances without deforming.

Metals also require lubrication to reduce friction and wear, but thermoplastics can be produced with self-lubricating properties that eliminate associated labor costs. Fiber-reinforced polymers and other specialty materials help prolong the service life of the entire construction system, lowering costs for both equipment manufacturers and end users.

Other benefits of using engineered thermoplastics for construction machines include:

- High fatigue resistance

- Low density

- Requires less energy to manufacture

- Minimal processing costs

- Easy to form into complex shapes

Construction Equipment Parts: Applications

Thermoplastic components are used in several highly critical wear applications due to their versatility and strength. Highlighted here are some of the most common examples.

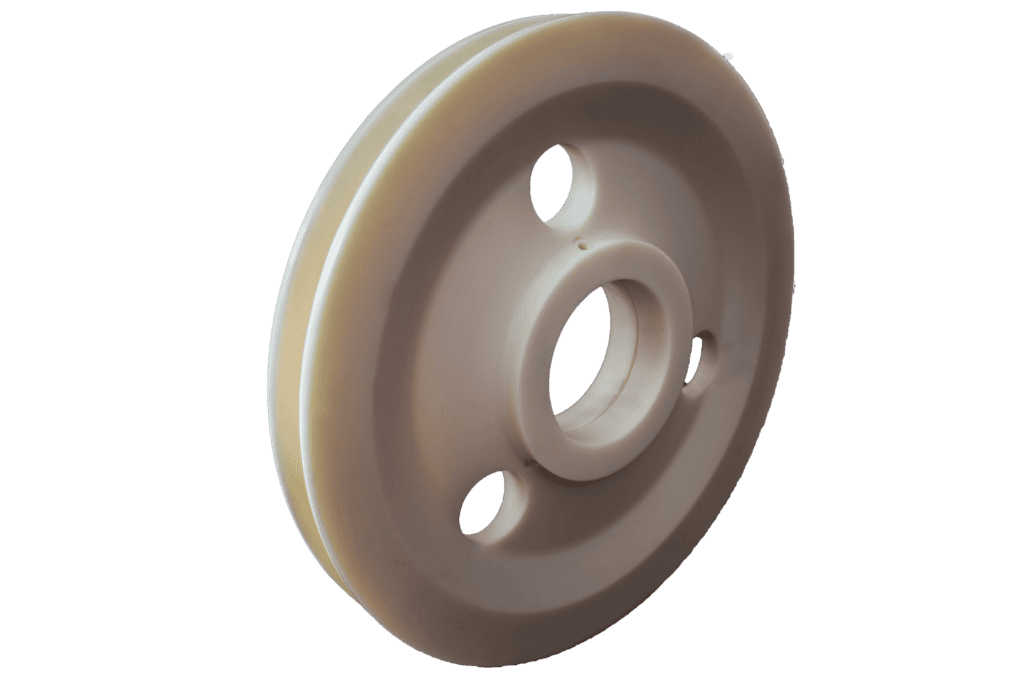

Nylon Sheaves

Nylon sheaves are superior to steel and aluminum because they are lightweight, strong, and can withstand heavy lifting, which is why they are crucial in lifting systems. The elasticity of nylon sheaves increases the contact area between the sheave groove and the wire rope, increasing load capacity and minimizing stress on the rope.

Plastic Wear Pads

Plastic wear pads are commonly used in bearing applications because they improve sliding properties, increase safety, and protect surfaces in various settings. These applications include telescoping equipment, fire truck ladders, cranes and aerial work platforms.

Other applications of thermoplastic construction machine parts include:

- Guide pads for extension cylinders

- Bearing shells for the bases of rotating booms

- Slide pads for telescopic booms

- Wheels

- Rollers

- Outrigger pads

- Outrigger floats

Construction Equipment Parts: Benefits

Timco technical thermoplastic components, like wear pads and sheaves, offer many benefits when used in construction machines. Some of these benefits are:

- Weight reduction

- Corrosion resistance

- Less wear on mating parts

- Lubrication-free operation

- Reduced wear and increased part life

- Reduced maintenance costs

- Noise reduction

- Lower production costs

Construction Equipment Parts: Selection

WS Hampshire, Inc. supplies a range of parts, including:

- Hose clamps

- Cable guides

- Sheaves and pulleys

- Scraper blades

- Outrigger float pads

- Rollers and wheels

- Slide pads for telescopic booms

- Hose guide sheaves

- Concrete polishing discs

- Outrigger pads or cribbing plates

- Insulation bushings

- Guide pads for extension cylinders

- Bearing shells for the rotating boom base

Construction Equipment Parts From WS Hampshire

Construction equipment needs to work smoothly, efficiently, and safely. Thermoplastic components are the ideal solution to achieve this goal. At WS Hampshire, we supply Timco engineering thermoplastics for your construction machines. We offer cost-effective, high-quality custom solutions for the construction industry and other markets like military, transportation, food processing, and oil and gas.

Contact us today to learn more about our construction parts. To ask about our composite or rubber materials, request more information through this form.