Compare Sheet Only:

Compare Tube Only:

POPULAR WEAR PAD MATERIALS SUPPLIED BY TIMCO INCLUDE:

Cast Nylon 6

Standard, heat stabilized, MoS2 filled, oil-filled, internally lubricated, FDA compliant and premium wear grades available for a broad variety of wear pad applications.

Calaumid ®

Nylon 6/12 with metal core for high load requirements and driven gears.

Acetal

When chemical/water resistance is required.

PET

Higher hardness and low absorption are required.

UHMW-PE

For lower load requirements and low water absorption.

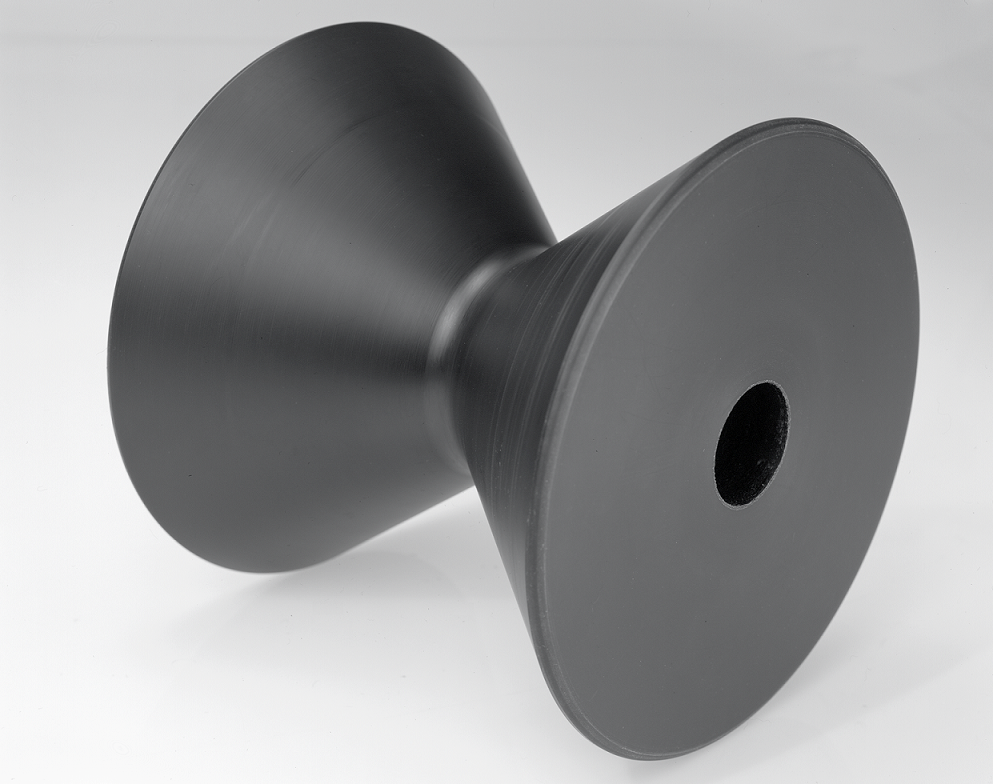

Various inserts available in wheels and rollers.

BENEFITS OF USING TIMCO TECHNICAL THERMOPLASTIC WHEELS AND ROLLERS

- Wear Resistance

- Protection of the running surface

- Motion and Noise Dampening

- Resistance Against Corrosive Influences

- Economical Production