WS Hampshire fabricates several unique plastic parts that are widely used in Steel and Aluminum Mills.

Nylon is the material of choice to replace components in the roll shops where steel thrust collars and drivers cause safety concerns for team members. Nylon weighs one seventh as much as steel and when used for parts that are handled as much as these, wear and tear on your team is greatly reduced. Slipper pads made from nylon not only are lighter and easier to handle than bronze, but also reduce the amount of wear on the spindle and roll neck.

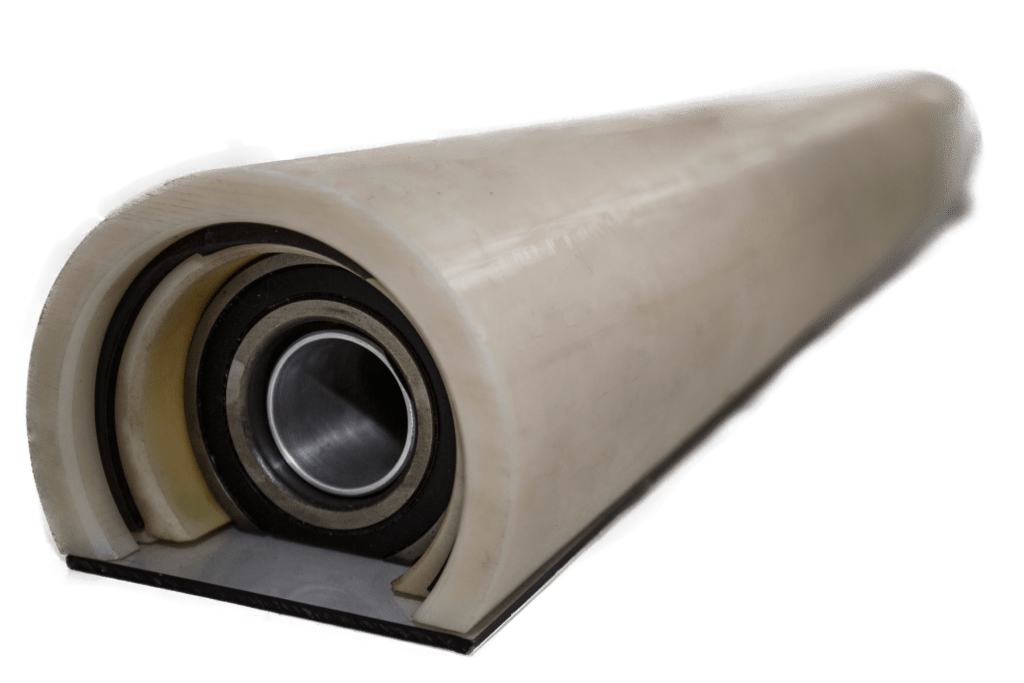

Table and gate rolls used on carry over tables or looper sections wear at a slower rate than those made from urethane and are much safer to handle. Urethane rolls require a large steel core to allow material to be cast on, meaning that they weight four times as much as those made from nylon.

Chock liners are also often replaced with nylon or PTFE as they offer superior wear properties and are easier & safer to install than steel or bronze.

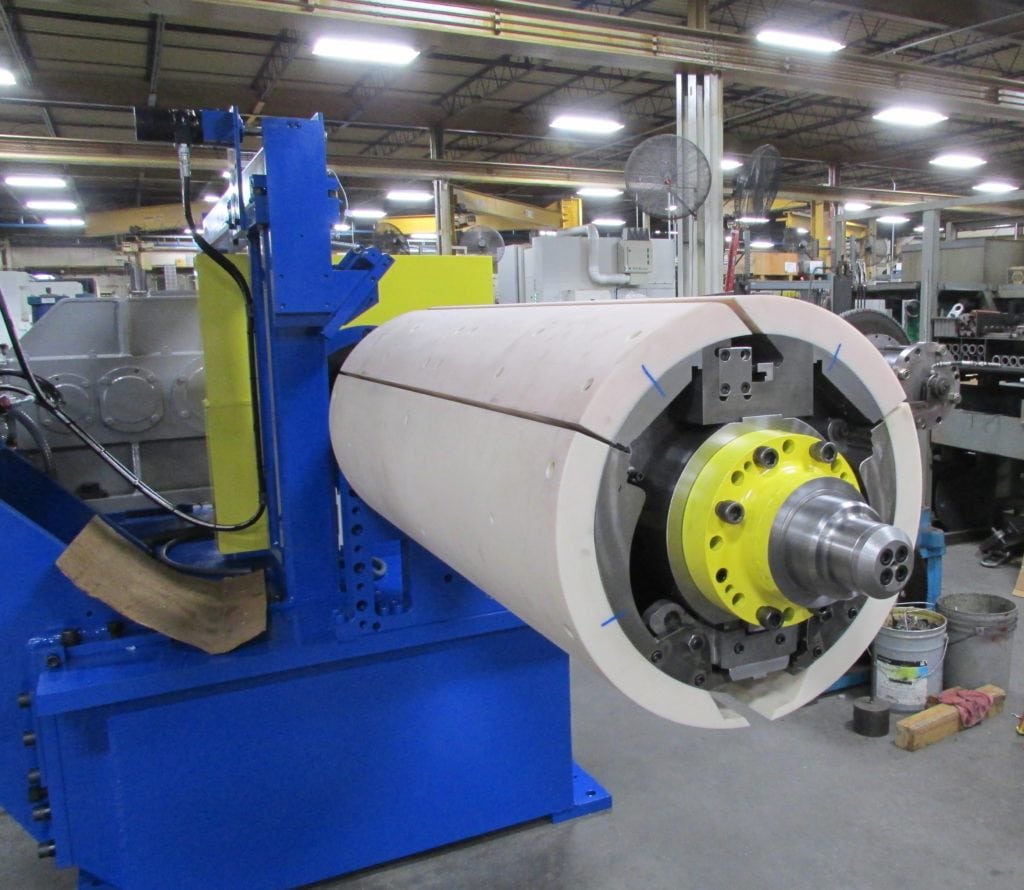

Processors often deal with different sized core sizes as they bring in coils from different producers. Nylon is the obvious choice to use as mandrel segments (or laggings) that allow for safe and fast changes to allow for processing these coils without changing the entire mandrel.