Compare Sheet Only:

Compare Tube Only:

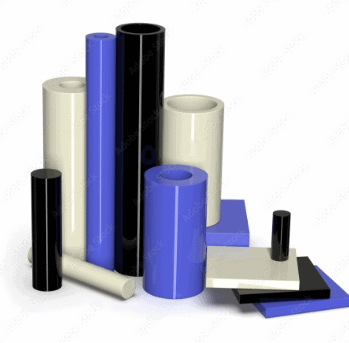

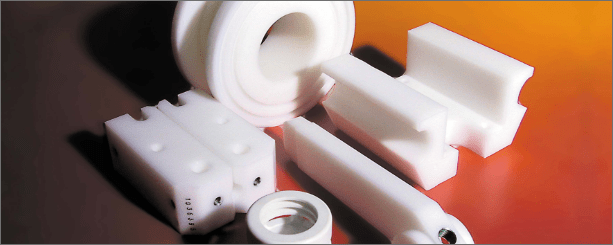

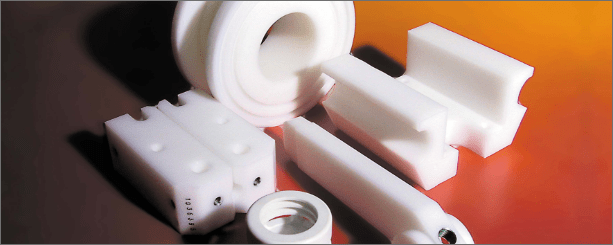

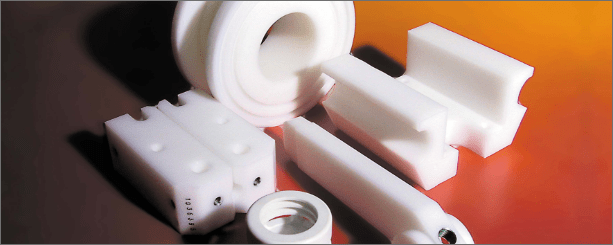

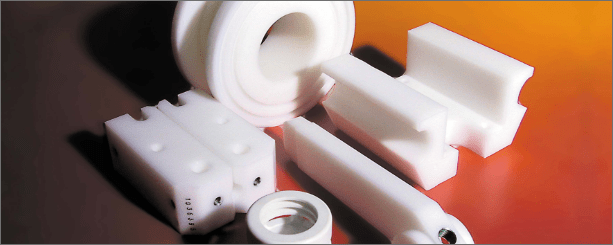

Ultra High Molecular Weight Polyethylene

UHMW is inherently very slick and chemically inert, making it a good basic choice for many bearing and wear applications. Sometimes referred to as a “poor man’s PTFE”, it shares many of the same characteristics: FDA compliance, bright white color, almost zero moisture absorption, excellent chemical resistance, and extremely low coefficient of friction / self-lubrication. Also, it has outstanding impact resistance (no break) down to cryogenic temperatures, the best-wet abrasion resistance of all materials (including metals) and a relatively low material cost. Its limitations include low compressive strength and limited heat resistance to 160F. Its high coefficient of thermal expansion makes tolerances more challenging to hold.

UHMW’s combination of properties makes it the ideal initial candidate for a broad range of applications, especially in food processing, material handling and heavy equipment. However, many modified versions are available which enhance specific properties:

- Reprocessed

- UV Stabilized

- Static-Dissipative / Conductive

- Ceramic Filled

- Solid Lubricant Filled

Solid Lubricant Filled

– Modified with solid lubricants, this version has the lowest coefficient of friction of any of the UHMW products. Inherent anti-static properties allow outstanding dusty environment service. Originally developed for package sorting equipment, neither cardboard nor shrink-wrap stick to it, and its lubricity also prevents conveyor squealing on turns. There are FDA compliant versions. - Oil Filled

Oil Filled

– This is the material of choice for packaging, bottling, and food processing and handling applications requiring FDA and USDA compliance and an extremely low coefficient of friction. However, due to UHMW’s almost zero moisture absorption, the oil freely migrates from the material (requiring multiple package layers for cleanliness during shipping and storage), and makes it a poor candidate in dusty environments - High Temp

- MoS2 Filled

- Cross-Linked / Glass Filled

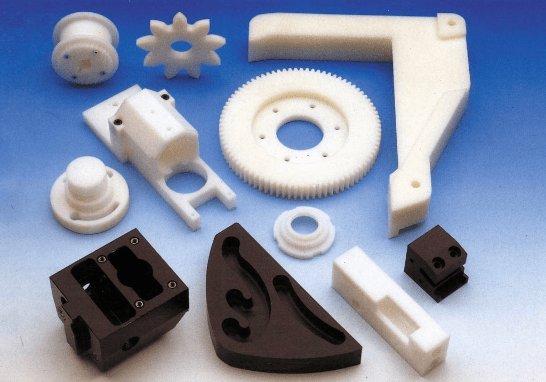

Nylon (Polyamide)

Nylon’s toughness, low coefficient of friction, and good abrasion resistance make it an ideal replacement for a wide variety of materials from metal to rubber. Weighs only 1/7 as much as bronze, it reduces or eliminates lubrication dependency, corrosion issues, and improves wear resistance, and offers sound dampening characteristics.

Nylon is available in both extruded and cast versions. While the material formulations available and the properties in each group vary slightly, the choice is usually made by size availability, and cost. Generally speaking, extruded nylon is most cost-effective in rod ≤ 2” diameter and ≤ 0.500” thick plate. Above those values, cast nylon is usually less expensive to purchase and available in shapes closer to the finished overall dimensions.

Casting allows for the production of shapes and near net shapes limited primarily on tool size/ capability. Parts in excess of hundreds of pounds have been produced by this method.

Extruded Nylons

Except as noted, all extruded nylons listed below are based on Type

6/6 nylon (PA66, or “Nylon 101”, an old resin designation)

- Natural / Black

- MoS2 Filled

- 30% Glass Filled

- Nylon 4,6

Nylon 4,6

– a high heat resistance extruded nylon, this material’s continuous use and heat deflection temperatures are 100F+ higher compared to unfilled Nylon 66. It is used where the heat/heat aging resistance, stiffness, creep resistance, and fatigue strength of PA6, PA66, acetal, and PET are insufficient. Generally available in metric diameters.

Cast Nylons

Except as noted, all the following materials are based on Cast Type 6 (PA6G) nylon; all materials are “G” = gravity cast (no additional pressure applied)

- Unfilled

- Heat Stabilized

- MoS2 Filled

MoS2 Filled

– grayish-black, this is the most popular version in North America, the addition of molybdenum disulfide increases the crystallinity which provides the additional load-bearing capability and some additional wear resistance, making it a cost-effective choice for many sheaves, gear, sprocket, and bushing applications - Plasticized

- Oil Filled

Oil Filled

– the addition of an oil lubricant adds self-lubricity, increasing the limiting PV capability and increases impact resistance while retaining the inherent toughness of the base nylon; the oil remains in the matrix and is only released as the material wears; it is available in various colors and FDA grade natural - MoS2 + Oil

- Solid Lubricant Filled

Solid Lubricant Filled

– first developed in the early 1980s, this version offers the lowest wear rate (1/10th that of unfilled) and highest PV capability over 5X that of unfilled) of any of the cast nylons; it has become the material of choice where high loads/speeds are encountered and lubrication is difficult or impossible to maintain; readily available in black, grey and red - Glass Filled

- Low Moisture / High Impact Grades

Low Moisture /

High Impact Grades

– these are either alloys of Type 6 and Type 12 nylon, or can be 100% Type 12, and are designed to merge the inherent strength of nylon with the dampening effects offered by higher durometer urethanes; these are used where an application sees severe impact, vibration, shock loads, fatigue resistance, or where lower moisture absorption than Type 6 is needed. The 6/12 alloy is also available with either oil or solid lubricants added to improve the wear resistance. Typical applications are those requiring compliance with mating surfaces and resiliency over repeated cycles such as valve seats, seal rings, gears, sprockets, high order impact pads - Nylon-Over-Metal

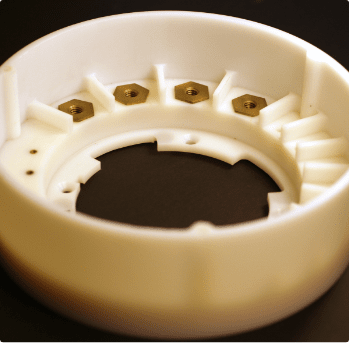

Nylon-Over-Metal

– this utilizes nylons’ capability to have knurled inserts in the ID of tubular shapes, where preventing of slippage over a bearing, the need to increase the bore ID for pressure relief on the nylon bore, higher press-fit strength is needed or power is being transmitted through the bore to an OD feature (gears, sprockets, drive rollers); this is available in a variety of formulations depending on the other application requirements

Acetal (Polyoxymethylene)

Acetals are generally characterized by very good dimensional stability and wear resistance (especially in wet environments), very good size availability (copolymer), good chemical resistance, mechanical properties that fit a wide range of structural and wear applications.

There are two basic types of acetal resins: homopolymer (repeating chain of the same basic molecules); and copolymer (repeating sequence of two alternating molecules). While they have some property differences, in 95%+ of all acetal applications, either one would work, and the choice primarily becomes one of size availability and cost. Both are FDA / USDA / NSF Standard 51 and Canada AG compliant; copolymer also is NSF Standard 61 compliant.

Homopolymer – most widely known by the DuPont tradename Delrin®, it is usually chosen because it is resident on an engineering drawing, or where its slightly higher physical properties & lower coefficient of thermal expansion are critical, such as very thin wall bushings and artificial foot keels. Available in a limited size range in rod and plate, an acetal homopolymer usually has a low-density center of the shape (micro-pinholes) and tends to outgas formaldehyde fumes when exposed to temperatures above 150F. Available in natural and black.

Within this grouping are specialty grades of Delrin®:

- Delrin® AF

- Delrin® AF Blend

- Delrin® AF DE-588

- Delrin® 127 / 527

- Copolymer

Copolymer

– while available in the USA as a custom item since the 1960s, extrusion grade copolymer was introduced commercially as a standard stock item in the USA in the early 1990s to address three issues inherent to homopolymer shapes: high internal stress, centreline porosity, and formaldehyde outgassing. Until this commercialization, a homopolymer represented about 90% of all the acetal shapes produced, today it is the exact opposite. European production is almost 96% copolymer shapes.Additionally, the copolymer has slightly better chemical resistance, impact resistance and is available in very large sections (up to 24” diameter rod and 10” thick plate have been run, up to 20” and 6” respectively are standard stock for machining), whereas homopolymer is very limited in sizes.

It is readily available in natural, black plus blue (both unfilled and metal detectable) specifically for food processing equipment.

Certain resins (such as Celcon® M-25) have achieved recognition by USP for orthopedic implant trial sizers; others (such as BASF® H4320) have recognition specifically for ice cream scraper blades.

Pet (Polyethylene Terephthalate)

A preferred replacement for Acetal where there is a concern for dimensional stability after machining. P.E.T. has excellent wear resistance and a low coefficient of friction, in addition to a very low water absorption rate and being FDA compliant. The low moisture characteristic makes P.E.T. ideal for electrical applications. The outstanding hardness and stiffness properties along with good chemical resistance enables P.E.T. to be the answer to many applications.

PET-GL

PET-GL is an internally lubricated thermoplastic polyester providing an optimal combination of enhanced wear resistance and dimensional stability (almost no moisture absorption and the lowest coefficient of thermal expansion in the lubricated, compared to the “3P’s” of general-purpose Nylon (PA), Acetal (POM) and unfilled PET. Containing a uniformly dispersed solid lubricant package, PET-GL provides a significantly lower wear rate and coefficient of friction than unmodified polyesters like PET or PBT and internally lubricated materials like Delrin® AF “Blend”, Delrin® 500CL, or Hydex® 4101L.

This material was developed in Europe where it is widely used, while gaining increased recognition in North America. One critical feature of this material is the ability to overcome “stick-slip” which can be best summarized as the jerkiness that linear bearings (wear pads) exhibit while transitioning from standstill to motion. It’s also sometimes called “stickage” or “sticktion”. This is especially important in heavy industrial equipment to prevent operational and safety concerns caused by ‘herky-jerky’ sudden movements of an extended boom carrying a load. Smooth operation is critical to load stability and safe operation- imagine carrying a load of drywall or riding on a fire truck ladder 4 stories in the air!

Lack of lubrication can be a contributing factor to stick-slip where over an extended timeframe, exposure to environmental conditions can wash away or degrade lubricants (grease, whatever…)… and so on.

PET-GL excels under both high pressure & velocity conditions. It is preferred for applications with soft metal (aluminum, stainless steel) mating surfaces, as it does NOT wear on softer surfaces as do nylon, acetal, and unfilled PET.

It also reduces frictional noise, far quieter than any lubricated nylon with severely cantilevered loads. The lubricant package can also allow reducing or eliminating the need for external lubrication in many applications.