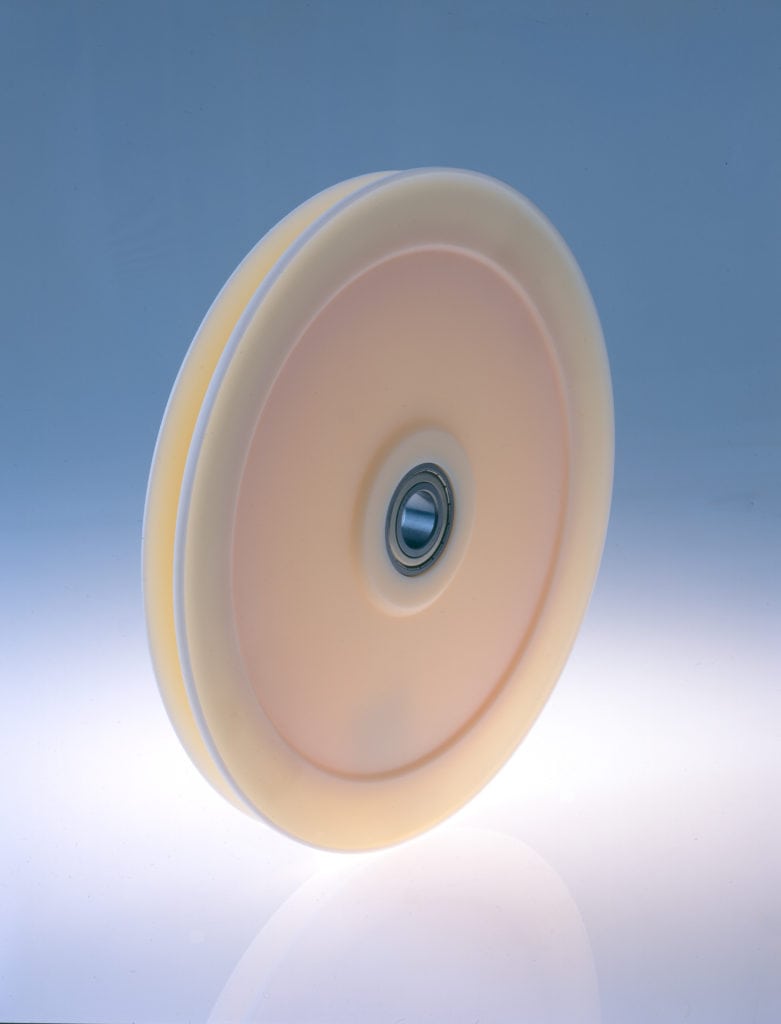

Composite and thermoplastic parts are used in the making of wire and cable, and we supply a variety of wear and structural components to the industry. Plastic components are lightweight making it easier for small diameter wire to turn idler sheaves without scuffing. Lighter weight plastic sheaves are easier to rotate and do not increase wire tension while preventing damage wire to the during manufacturing. Our sheaves are machined to a smooth groove finish for the lowest friction possible in use. Manufacturers of fiber optic cable, RF (coaxial) wire, aluminum, and copper wire all use nylon or UHMW-PE sheaves custom fabricated by WS Hampshire, who is the largest supplier of fabricated non-metallic sheaves in North America. You can rely on our knowledge and experience to help you select the most suitable material for your equipment and help you design your finished component. We supply single groove, multi-groove and interlocking sheaves with both flat and round grooves and offer many other high quality wear resistant fabricated parts for the wire and cable industry including guide wheels, rollers, capstans, drawing rings, drawing cones and trunnion rollers for stranding machines.

Our Parts Offer:

- Improved Equipment Efficiency and Performance

- No Marking of the Wire

- Better Rotation Without Increasing Wire Tension

- Excellent Groove and Wire Life with Fewer Cable Breaks

- Sheaves Can Be Supplied With or Without Bearings, Snap Rings or Bushings

- Long Part Life

- Reduced Maintenance Costs for Equipment

- Ability to Run Without Lubrication

- Reduced Noise and Vibration

- Reduced Wear on Mating Parts

Parts WS Hampshire Supplies:

- Wire Sheaves

- Guide Wheels and Rollers

- Eyelet, Hook, Traverse and Snail Guides

- Trunnion Rollers for Stranding Machines

- Capstans

- Canvas Rods

- Drawing Rings

- Drawing Cones

- Bearings and Bushings