Applications in Steel and Aluminum Rolling Mills

Ryertex and Timco Technical Plastics are widely used in aluminum and steel rolling mills as an alternative to steel, bronze, brass, and other composite materials in situations where weight, temperature, water, and lubrication are concerns. These materials are resilient, long-lasting, and versatile, and they won’t cause problems with surface quality by marking the steel.

Ryertex Applications in Steel & Aluminum Rolling Mills

Ryertex is a series of fiber-reinforced plastic composites commonly used as electrical insulation or as an alternative to metal in wear situations involving high speed, load, and temperatures or where the loss of lubrication is a risk.

Applications

Common applications of Ryertex include:

- Hot strip mills. Ryertex strippers and wipers offer the sealing required to safeguard expensive work rolls while requiring fewer change-outs than OEM-specified material grades. This leads to lower operational expenses and labor hours.

- Finishing lines. Finishing lines benefit from using Ryertex to line carry-over tables to protect their equipment and the final sheet. This reduces quality concerns and equipment replacement expenses.

- Bar and plate mills. Ryertex fiber bearings that are engineered to handle severe shock loads and wear at slower rates are used in old-school bar and plate mills. Ryertex is widely utilized in these situations to replace steel, bronze, or brass in troublesome applications that are difficult to lubricate or are exposed to high loads, temperatures, and impacts.

Applications of Timco Technical Thermoplastics in Steel & Aluminum Rolling Mills

Engineering plastics are a type of polymer noted for their versatility, great mechanical strength, and ability to be melted and reformed into various shapes. Plastics have been used for decades to substitute metal in situations where corrosion resistance, weight reduction, or a low coefficient of friction are required to minimize wear on mating components.

Timco Technical Thermoplastics are used in roll shops and finishing processes where pads, bumpers, and guides are required to protect the equipment and the product. Plastics provide lightweight handling and installation, extended part life, and decreased maintenance requirements in several applications.

Applications

Applications of Timco Technical thermoplastics include:

- Table and gate rolls. Table and gate rolls featuring roll bodies made of cast nylon wear at a lower rate compared to urethane rolls and offer safer replacement, as nylon rolls don’t need hefty steel cores. To help your cost-cutting and sustainability initiatives, we can reconstruct your worn nylon rolls, which saves around half the cost of replacement rolls and keeps old rolls out of waste piles.

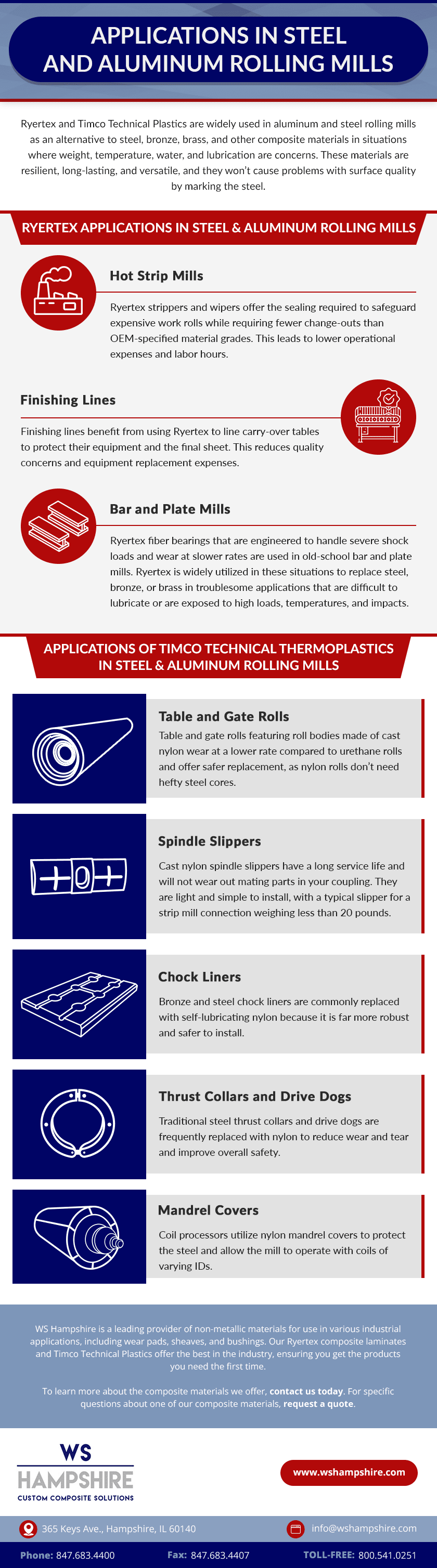

- Spindle slippers. WS Hampshire provides cast nylon spindle slippers as an alternative to the heavy bronze spindle slippers that many mills are used to. Cast nylon spindle slippers have a long service life and will not wear out mating parts in your coupling. They are light and simple to install, with a typical slipper for a strip mill connection weighing less than 20 pounds. Their high modulus of elasticity also reduces vibration and noise.

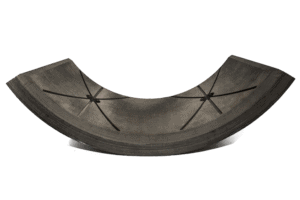

- Chock liners. Bronze and steel chock liners are commonly replaced with self-lubricating nylon because it is far more robust and safer to install.

- Thrust collars and drive dogs. Traditional steel thrust collars and drive dogs are frequently replaced with nylon to reduce wear and tear and improve overall safety.

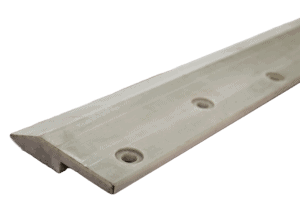

- Mandrel covers. Coil processors utilize nylon mandrel covers to protect the steel and allow the mill to operate with coils of varying IDs.

Benefits of Using Plastics in Steel and Aluminum Rolling Mills

There are numerous ways in which plastics can improve the operation of your steel or aluminum rolling mill, resulting in increased efficiency and safety and lowering overall costs. These advantages include:

- Noise Reduction

- Less Downtime

- Vibration Dampening

- Capacity to Operate Without Lubrication

- Lower Wear on Mating Parts

- Lightweight Design for Safe Handling and Installation

- Extended Part Life

- Lower Operating Costs

- Quick Turnaround Time

- Lower Maintenance Costs

- Elimination of Corrosion

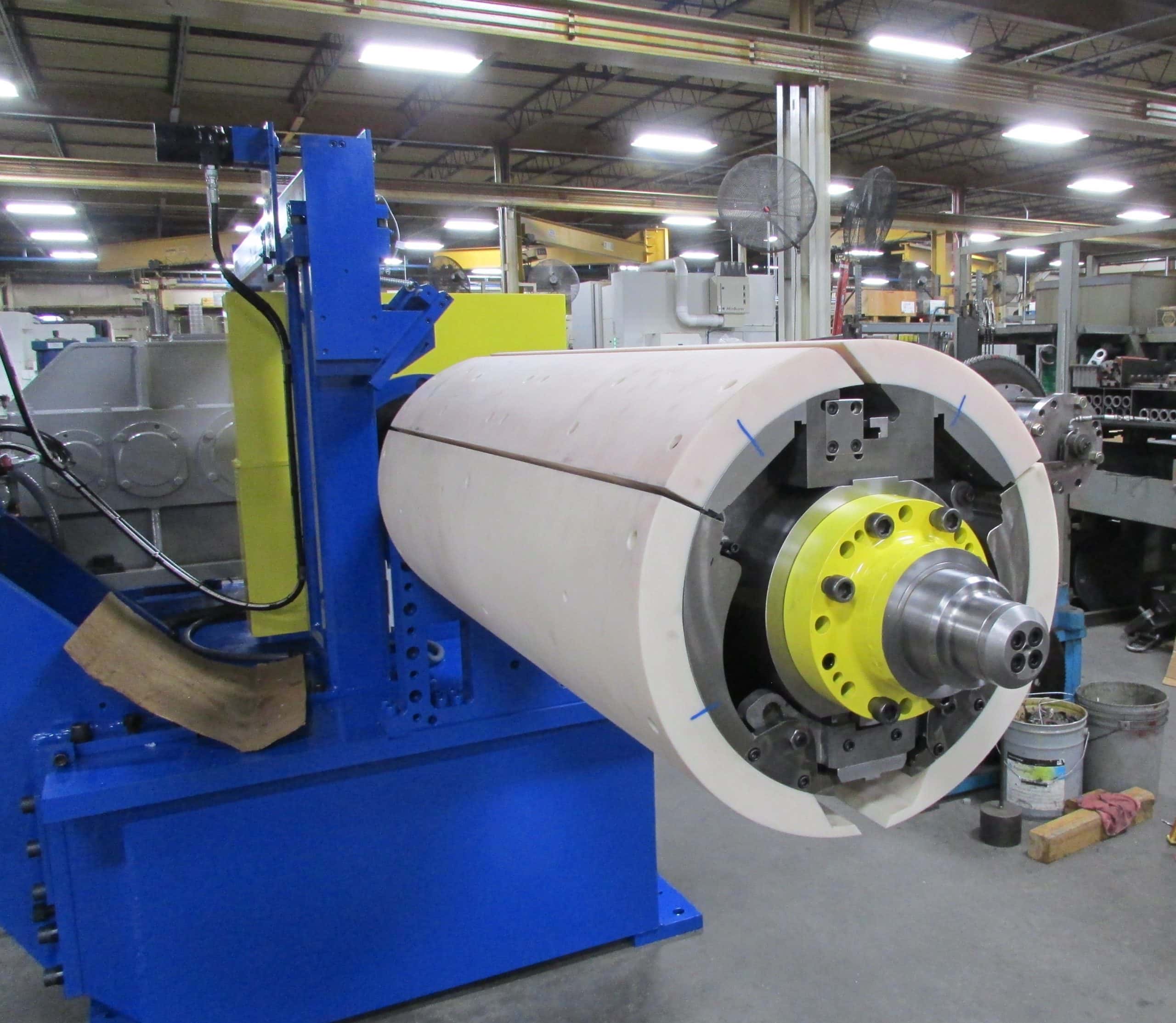

Rolling Mill Parts Produced By WS Hampshire

At WS Hampshire, we can provide the following rolling mill parts:

- Tapered Sleeve

- P&N Roller Bearings

- Carts and Mill Stands

- Block for Pin

- Drive Coupling Blocks and Inserts

- Thrust Collars

- Water-Cooled Bearings for Mill Stands

- Table and Accumulator Roll Bodies and Roll Assemblies

- Stripper Tips & Wiper Blades

- Drive Dogs

- Fiber and Caster Bearings

- Bearings for Zero Section Casting Rolls, Charge

- Spindle Slippers

- Chock Liners

- Filler Plates for Uncoiling/Recoiling Mandrels

Composite Materials from WS Hampshire

WS Hampshire is a leading provider of non-metallic materials for use in various industrial applications, including wear pads, sheaves, and bushings. Our Ryertex composite laminates and Timco Technical Plastics offer the best in the industry, ensuring you get the products you need the first time.

To learn more about the composite materials we offer, contact us today. For specific questions about one of our composite materials, request a quote.