What Is a Wear Pad?

Wear pads are used to protect surfaces, improve sliding properties, and increase safety in a wide variety of industrial applications. Composite wear pads made from Ryertex can be found in steel and aluminum mills, industrial saws, and other processing equipment, while the lifting industry often utilizes thermoplastics, such as our Timco technical thermoplastics. Cranes, firetrucks, and aerial work platforms benefit from the combination of wear resistance, high strength, noise reduction, and greatly reduced friction.

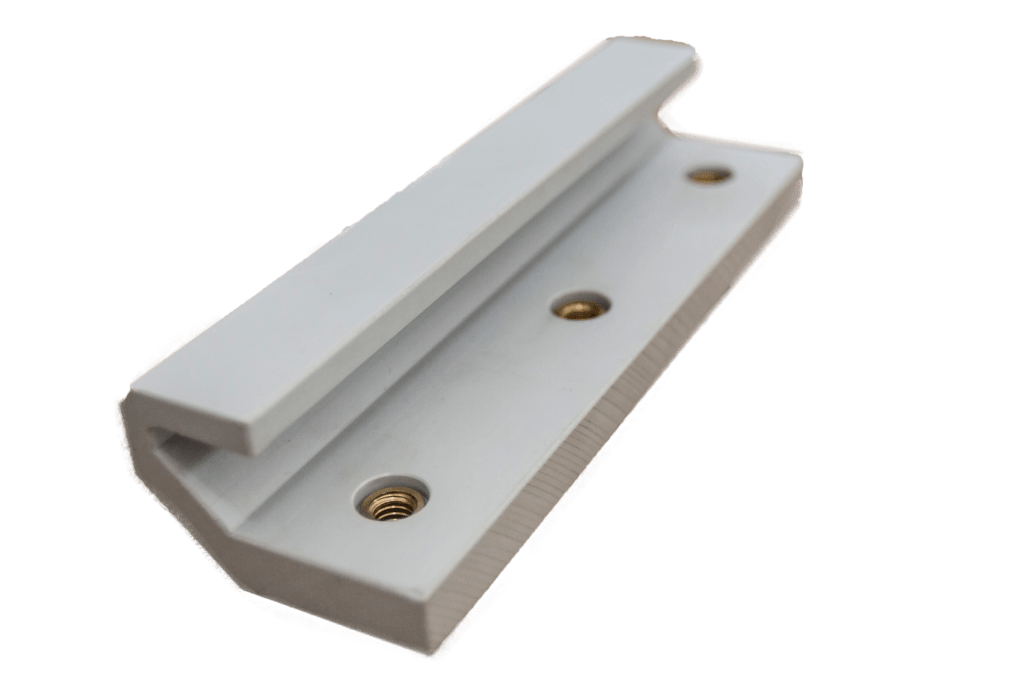

WS Hampshire offers a wide range of material options and a broad manufacturing size capability. Wear or slider pads can be made to any size and can be supplied with or without mounting inserts. Because we offer many grades of nylon and other engineering plastic materials, you can select the best combination of economics and performance to fit your needs. Our team will be happy to review your application conditions and recommend the optimum material for your application.

Types of Wear Pad Materials We Fabricate

At WS Hampshire, we specialize in fabricating wear pads out of a variety of nonmetallic materials, such as:

- Cast Nylon 6 Wear Pads: Our custom produced cast nylon wear pads are versatile, durable, and wear- and abrasion-resistant. They come in a variety of thicknesses, widths, and lengths to suit any application. Their self-lubricating features, combined with resistance to corrosion and chemicals, make them perfectly suited for challenging environments. Ideal for industries requiring robust material performance, nylon wear pads ensure longevity and reliability in operation.

- UHMW-PE Wear Pads: Ultra-high-molecular-weight polyethylene (UHMW-PE) wear pads are the go-to for heavy-duty impact protection. Known for their exceptional impact resistance and low friction, these pads endure the harshest conditions while maintaining smooth operations.

- Acetal Wear Pads: Acetal, also known as polyoxymethylene (POM), is prized for its high strength and minimal friction. It offers superior wear properties in both wet and dry environments. The engineering plastic is an excellent option for complex applications that demand precise tolerances.

- PET Wear Pads: PET wear pads are lightweight, and strong. They are often used in applications with higher load requirements and food and beverage processing, as PET is food-safe.

- Ryertex Wear Pads: Ryertex composite wear pads are engineered for the rigors of heavy industrial use, including in steel and aluminum mills. Their proven performance in industrial processing equipment underscores their exceptional durability and adaptability. Ryertex pads are designed to withstand the demands of high-temperature, high-load, and high-stress environments.

Each material we fabricate is tailored to meet specific industry needs, ensuring optimal performance and extended equipment life. Our commitment to quality and innovation positions us as a leader in wear pad solutions.

Note that thermoplastic wear pads do have special storage recommendations in order to retain dimensional stability.

Common Wear Pad Industry Use Cases

Wear pads are important components for many applications, particularly:

- Construction Machines: Wear pads are crucial in construction, ensuring the longevity and performance of heavy-duty machinery like concrete pumpers, cranes, aerial work platforms, and earthmovers. Industrial wear pads absorb shocks and reduce friction to prevent premature wear and tear between mating components, allowing for uninterrupted operation and maintenance savings.

- Mining Machines: UHMW-PE wear pads shine in marine and mining settings, resisting saltwater, chemicals, and fuel. Their chemical inertness means they will not leach into waterways or damage ecosystems. UHMW-PE pads can also withstand extreme weather, allowing them to last longer than other wear pad materials and minimize replacement costs.

- Transportation Equipment: Large, heavy-duty tow trucks, buses, semi-trailers, and fire engines require wear pads in multiple key locations, such as the extendable boom. Positioned in these high-wear locations, wear pads protect transportation equipment from costly damage and enhance the safety and efficiency of their operations.

Benefits of Using Timco Wear Pads

When you use our Timco wear pads, you’ll benefit from the following:

- Extend Wear Pad Life: Excellent wear resistance and a low coefficient of friction make our parts last longer.

- Reduce System Maintenance Requirements: Many wear or slider pad material options are self-lubricating or oil-filled, reducing or eliminating the need for external lubrication. Our wear pads also reduce wear on mating surfaces and other system parts, leading to additional cost savings.

- Improved Efficiency and Safety: Lightweight composite components increase operational efficiency and reduce noise and vibration. They are also safely and easily handled.

Quality Grade Industrial Wear Pads by WS Hampshire, Inc.

At WS Hampshire, Inc., we pride ourselves on providing top-quality wear pads that meet or exceed industry standards. Whether you’re in construction, mining, or transportation, our wear pads offer the durability and efficiency your operations need. Request a quote today to see how our wear pads can serve your project.