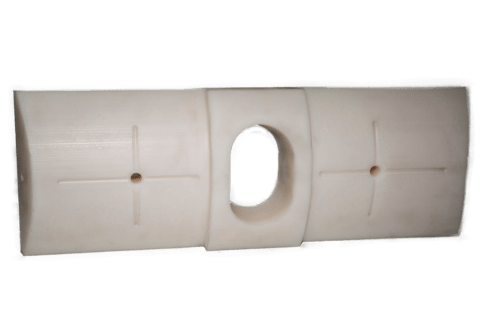

In business for more than 100 years, WS Hampshire, Inc. has an industry-wide reputation for producing high quality, non-metallic parts that withstand the toughest industrial conditions. Typically made from bronze and used as a coupling insert for use in a steel mill, we machined the nylon slipper pad shown here. Nylon possesses the required high impact strength to survive in the severe environment of a rolling mill and will not wear the spindle, roll, or coupling housing.

In business for more than 100 years, WS Hampshire, Inc. has an industry-wide reputation for producing high quality, non-metallic parts that withstand the toughest industrial conditions. Typically made from bronze and used as a coupling insert for use in a steel mill, we machined the nylon slipper pad shown here. Nylon possesses the required high impact strength to survive in the severe environment of a rolling mill and will not wear the spindle, roll, or coupling housing.

Plus… using nylon in this application is a welcome relief to maintenance crews as part weight is reduced by approximately 85%. This makes for a much easier and safer change out!

Working with the customer specifications, our manufacturing technicians applied a combination of manual and precision CNC machining processes to create the complex geometrical curves, angles, and edges. Their advanced skill set, combined with our workhorse Haas VMC enabled us to keep within tight ± 0.005” tolerances. A deburring step ensured there was no trace of particulate left on the surface that would impede its performance. Careful dimensional and visual inspections at critical intervals in the process ensured we met the customer requirements.

If you would like to learn more about this project, or you have a similar project and would like to discuss the details, contact us today.