Ryertex and Timco Technical Plastics are ideal materials for wear and structural components as they will naturally resist the harsh, wet environment of pulp, paper, and lumber mills. Chemical and abrasion resistance, toughness, and reliability are necessary for all parts found on pulp, paper and lumber processing equipment and we have decades of experience manufacturing the list of parts you see below.

In some mills, Ryertex has been used to replace bronze bearings in dryer cans and felt rolls. Self-lubricating grades have proven to add a measure of reliability in bearing applications where lubrication is frequently lost and can save thousands of dollars in unplanned shutdowns. No longer will you receive that 3am emergency phone call as proven in this high level trial.

Our Parts Offer:

- Low Water Absorption

- Chemical and Corrosion Resistance

- Long Part Life

- Reduced Maintenance Costs for Equipment

- Lower Cost in Use

- Ability to Run Unlubricated

- Reduced Noise

- Reduced Wear on Mating Parts

- Fast Turnaround Time

Parts WS Hampshire Supplies:

- Suction Box Covers

- Scraper Blades

- Wire Rope Sheaves and Sheave Assemblies

- Wear Plates

- Slider Pads

- Bearings, Bushings

- Rollers and Wheels

- Conveyor Liners

- Chain Guides

- Electrical Components

- O-Ring Retainers

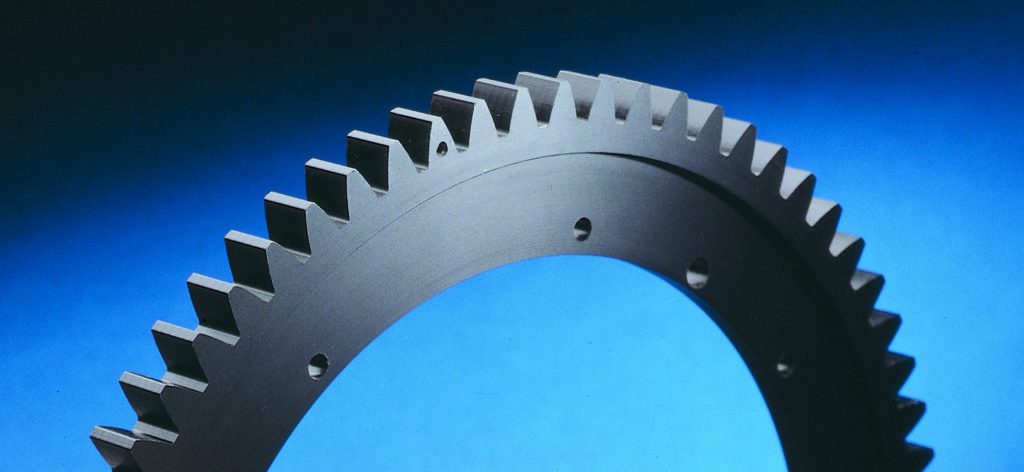

- Gears/Sprockets

- Saw Guides

- Safety Enclosures

- Cleaner Cones

- Roll Coverings

- Sorter Hooks

- Carry-Over Wheels

- Chip Screens

- Flights

- Gaskets/Seals

- Lantern Rings