European cast nylon producers, and injection molding resin guides, report both “dry” and “conditioned” data for nylon-based materials which are hygroscopic (absorb moisture from the air) and can absorb upwards of 8% moisture by weight at saturation (compared to 0.8% for acetal).

This is a completely reversible physical reaction as the higher the humidity, the faster nylon will absorb moisture. However, it only absorbs moisture until it is saturated and can absorb no more. Conversely, it releases moisture and dries out when exposed to dryer air.

Under normal conditions, nylon will reach equilibrium in a short period of time, though time will vary depending on thickness. However, “equilibrium” is a relative term given its environment at a given time. So, equilibrium will vary from Minnesota to Louisiana, and from winter to summer.

Dry and conditioned data

Nylons are semi-crystalline polymers, with both crystalline and amorphous regions. The tight crystalline regions give nylon much of its strength, stiffness and wear resistance.

The amorphous regions absorb the water, which then bonds to the polymer chain and force the crystalline structures apart. The result is nylon parts that swell and show diminished mechanical properties. Water actually acts as a plasticizer, making the nylon softer while increasing toughness and elongation. Since these effects happen when polyamides are exposed to moisture, they must be considered when designing a part.

What is the difference between data quoted for dry and conditioned data for plastic materials? And why is this most significant for nylons

Dry: Data with equivalent moisture content as when it was run (typically <0.2%).

Conditioned: data after absorbing environmental moisture at 50% relative humidity prior to testing.

Effect of moisture on properties

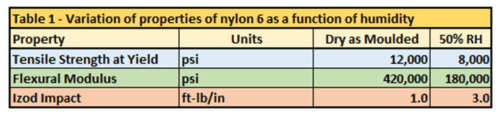

In general, as moisture content rises, impact strength and other energy absorbing characteristics increase. Some other properties decline

Variation of properties of nylon 6 as a function of humidity

Dimensional stability

When designing nylon components, it is important to consider that dimensions will be dramatically affected by temperature and humidity. This is especially so on long parts. If the dimensional change is unacceptable, you should consider acetal (POM) or polyester (PET) as alternative materials as they provide additional stability in wet environments.

At room temperature and 50% relative humidity, equilibrium moisture content for nylon tends to remain around 2%, which corresponds to an increase in size of roughly 0.5 – 0.6%. Under similar conditions, acetal absorbs roughly 0.2% moisture by weight and grow around 0.2%.

Variations between nylon grades

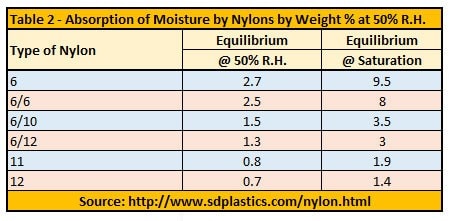

How much the different properties change depends a great deal on the chemistry of the polymer itself. Nylon types include 6, 6/6, 4/6, 6/12, 11, and 12 (types = number of carbon atoms in the molecule) Polyamide 12, for example, doesn’t absorb as much moisture as Polyamide 6, so Polyamide 12’s properties don’t fluctuate as much with moisture.

Absorption of Moisture by Nylons by Weight % at 50% R.H. and Saturation @ 23°C (resin data)

Additionally, as nylon absorbs moisture beyond equilibrium, its surface becomes “amorphous” (spongy), and wear resistance is lower. The addition of liquid or solid lubricants to the nylon offsets most of the decrease.

Need help deciding what to use? The experts at WS HAMSHIRE can explain this and more, so you can make the best material decisions for your needs! Call us – you’re in the right place!

Tom Connelly is a self proclaimed “Street Engineer” with over 40 years in the plastics industry.