Major industrial manufacturers turn to WS Hampshire for custom components and assemblies made from composite materials and plastics. We supply Timco Technical Thermoplastics and Ryertex Industrial Laminate components that are durable, versatile replacements for metal components. Steel and aluminum mills, in particular, benefit greatly from using non-metallic thrust collars, tube rolls, and filler plates. Learn more about how mills use these components and how WS Hampshire’s products and capabilities can support your operations.

How Mills Use These Components

WS Hampshire serves aluminum and steel mills with long-lasting, specialty components that make operations run more smoothly. We manufacture plastic parts from high-quality plastics like Nylon or PTFE, which offer cost-effective, reliable performance. Nylon is just 14% the weight of steel, and it offers excellent wear resistance for slipper pads, rolls, chock liners, and mandrel segments. As more lightweight components, nylon parts are easier to handle and safer to install than bronze or steel components by reducing worker fatigue and the risk of injury.

Thrust Collars

Thrust collars typically sit along pipelines, compressors, and shafts to absorb load force and protect adjacent components. Internal pressure or thrust load forces generate heavy pushing or pulling forces that would otherwise transfer from part to part, causing malfunctions or breakage.

In aluminum and steel mill applications, thrust collars manage axial load along a shaft, redistributing the force to prevent overload. Other common applications of thrust collars in these environments include:

- Spacer. Roller collars can fill space along a shaft to ensure different parts are properly positioned.

- Safety stop. Thrust collars can limit the movement of heavy or forceful machinery, reducing safety risks to nearby people or other equipment.

- Locks. Thrust collars can lock bearings into place so they don’t move during milling operations.

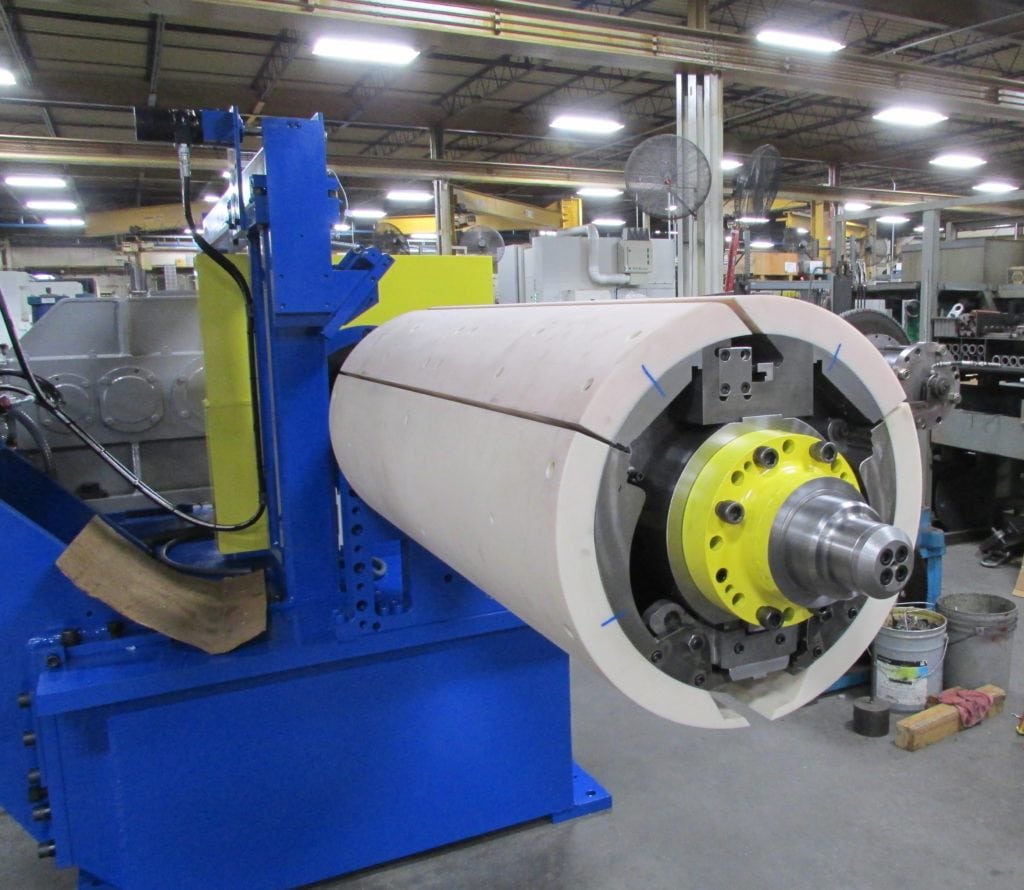

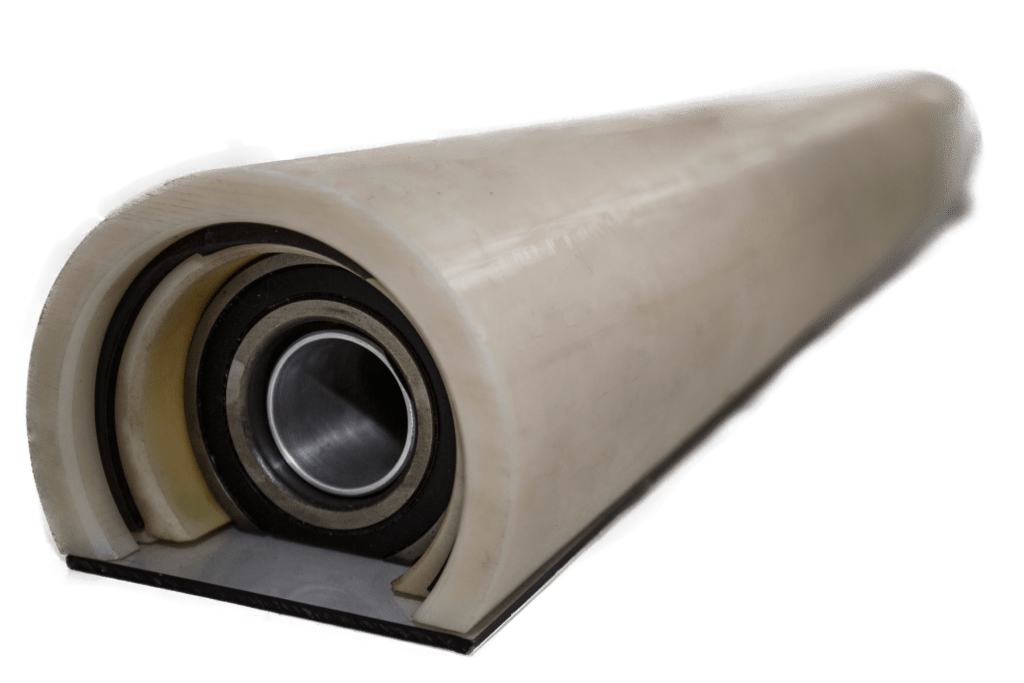

Tube Rolls and Filler Plates

Tube rolls play a fundamental part in shaping flat metal pieces and tubes. Aluminum and steel rolling mills can use tube rolls and forming stands to progressively shape flat workpieces or metal blanks into precisely shaped cylinders. Technicians feed the flat metal against forming rolls, which gradually bend the metal and give it a rounded shape. The bending is gradual and performed across multiple stages to avoid stressing and cracking the metal. Once the tube rolls form the metal into a cylinder, technicians can weld the edge shut to create closed cylinder forms.

Filler plates can help manage uneven loads when rolling aluminum and steel. The plates can fill gaps and create secure structural connections between separate components. During the metal manufacturing process itself, mills can use specialty filler plates to coil and uncoil mandrels during slitting operations.

WS Hampshire’s Fabrication Capabilities

WS Hampshire serves industrial markets as a trusted laminate and composite fabricator. We offer comprehensive, end-to-end manufacturing of custom non-metallic parts, including CNC machining, plastic forming, and film fabrication. Our CNC fabrication capabilities include:

- CNC machining

- CNC milling

- CNC drilling

- CNC routing

- CNC sawing

- CNC lathe turning

We can produce plates up to six inches thick and tubes up to 50 inches in diameter.

Partner With Us to Upgrade Your Mill

Steel and aluminum mills can increase productivity and reduce equipment costs by upgrading their milling equipment with non-metallic components. Transitioning away from traditional components like steel thrust collars to nylon, PTFE, and thermoplastic parts offers a wide range of benefits, including less noise and vibration, less downtime, and cleaner production without lubrication.

WS Hampshire is here to help with high-quality fabrication services of your custom parts, so you have exactly the right components for each piece of equipment at your milling facility. Contact us today to learn more about our products and capabilities.