“Dry” Versus “Conditioned” Nylon Explained

Leave a CommentEuropean cast nylon producers, and injection molding resin guides, report both “dry” and “conditioned” data for nylon-based materials which are hygroscopic (absorb moisture from the air) and can absorb upwards of 8% moisture by weight at saturation (compared to 0.8% for acetal).

This is a completely reversible physical reaction as the higher the humidity, the faster nylon will absorb moisture. However, it only absorbs moisture until it is saturated and can absorb no more. Conversely, it releases moisture and dries out when exposed to dryer air.

Under normal conditions, nylon will reach equilibrium in a short period of time, though time will vary depending on thickness. However, “equilibrium” is a relative term given its environment at a given time. So, equilibrium will vary from Minnesota to Louisiana, and from winter to summer.

Dry and conditioned data

Nylons are semi-crystalline polymers, with both crystalline and amorphous regions. The tight crystalline regions give nylon much of its strength, stiffness and wear resistance.

The amorphous regions absorb the water, which then bonds to the polymer chain and force the crystalline structures apart. The result is nylon parts that swell and show diminished mechanical properties. Water actually acts as a plasticizer, making the nylon softer while increasing toughness and elongation. Since these effects happen when polyamides are exposed to moisture, they must be considered when designing a part.

What is the difference between data quoted for dry and conditioned data for plastic materials? And why is this most significant for nylons

Dry: Data with equivalent moisture content as when it was run (typically <0.2%).

Conditioned: data after absorbing environmental moisture at 50% relative humidity prior to testing.

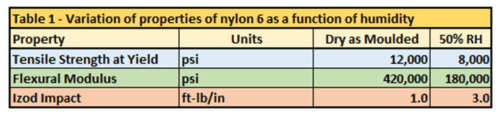

Effect of moisture on properties

In general, as moisture content rises, impact strength and other energy absorbing characteristics increase. Some other properties decline

Variation of properties of nylon 6 as a function of humidity

Dimensional stability

When designing nylon components, it is important to consider that dimensions will be dramatically affected by temperature and humidity. This is especially so on long parts. If the dimensional change is unacceptable, you should consider acetal (POM) or polyester (PET) as alternative materials as they provide additional stability in wet environments.

At room temperature and 50% relative humidity, equilibrium moisture content for nylon tends to remain around 2%, which corresponds to an increase in size of roughly 0.5 – 0.6%. Under similar conditions, acetal absorbs roughly 0.2% moisture by weight and grow around 0.2%.

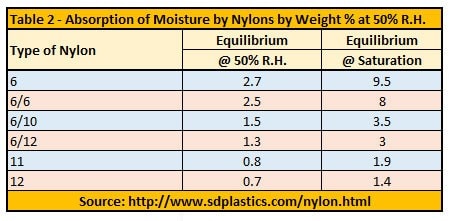

Variations between nylon grades

How much the different properties change depends a great deal on the chemistry of the polymer itself. Nylon types include 6, 6/6, 4/6, 6/12, 11, and 12 (types = number of carbon atoms in the molecule) Polyamide 12, for example, doesn’t absorb as much moisture as Polyamide 6, so Polyamide 12’s properties don’t fluctuate as much with moisture.

Absorption of Moisture by Nylons by Weight % at 50% R.H. and Saturation @ 23°C (resin data)

Additionally, as nylon absorbs moisture beyond equilibrium, its surface becomes “amorphous” (spongy), and wear resistance is lower. The addition of liquid or solid lubricants to the nylon offsets most of the decrease.

Need help deciding what to use? The experts at WS HAMSHIRE can explain this and more, so you can make the best material decisions for your needs! Call us – you’re in the right place!

Tom Connelly is a self proclaimed “Street Engineer” with over 40 years in the plastics industry.

Happy Thanksgiving

Leave a Comment

Dear customers, vendors, and partners,

Thank you for allowing us to do what we do. As we enter the Thanksgiving week, we are reminded again that we would not be in the amazing position that we are today without the trust, support, and commitment that we receive from you every day. Whether you are customer number one, a supplier that we only buy from sporadically, or somewhere in the middle, please know that we are thankful for all that you do in allowing us to succeed. We truly could not do it without you.

From our team to yours, have a Happy Thanksgiving!

-WS Hampshire

The Process of Annealing Plastics

Leave a Comment

Although the chemical-mechanical properties of plastic are largely determined by their chemical composition, their properties can be modified via heat treatment. One of the most commonly used heat treatment methods to alter the mechanical properties of plastic is annealing. (more…)

NYLON – WHY ARE THERE SO MANY AND WHAT ARE THE DIFFERENCES?

Leave a Comment

Nylon – chemically polyamide (PA, not to be confused with polyimide, PI) was invented in 1935 by DuPont’s Wallace Carothers (PA 6/6). Nylon 6 (PA 6, extruded), or polycaprolactam, was developed by Paul Schlack at IG Farben to reproduce the properties of nylon 6/6 without violating DuPont’s patent. Initially used in fibers to replace silk in parachutes, stockings etc, these resins established the basic principles of polymer chemistry that have made plastics such a ubiquitous part of our lives today. Nylon was also injection molded into components for the automotive market with varying degrees of success…people back then disliked nylon timing chain sprockets as they constantly stripped out!

(FUN FACT – “NYLON” was originally DuPont’s tradename, but DuPont didn’t protect it and it became so commonly used that they lost the right to it – today it is “ZYTEL®”)

Generally, nylon machined parts have a robust combination of properties, including high strength-to-weight ratio, toughness and inherent wear resistance. Stock shapes in 6/6 nylon are all extruded; in type 6, it can be either extruded (Europe) or cast (worldwide). While there are slight property differences, usually the decision between PA 6/6 and 6 involves either size and/or specifically modified version availabilities.

PA 6/6, sometimes referred to as Nylon 101 (old DuPont callout), is available in natural (off white), black, glass filled and specialty grades (low smoke, flame retardant, heat stabilized, impact modified). There are no enhanced wear resistant versions currently available.

NOTE: The crossover point [cost versus size] between unfilled extruded PA 6/6 and cast PA 6 is about 2.5” diameter rod, and .500” plate, over which cast PA 6 costs less to make.

PA 6 – in North America, 99+% of PA6 is cast, so we’ll stick to that technology. Cast nylon was first invented in Europe in the 1950’s and introduced in the US in the early 1960’s. Since it is made by combining two liquid feedstreams into a tool which react to become PA 6, additives are much easier to incorporate, and a wide range of sizes and shapes are readily available (from thin plate to custom castings weighing hundreds of pounds).

Here are the most popular grades of cast PA 6 currently available:

MODIFIER | COLOR | BENEFIT |

| Unfilled | Natural, black | General purpose |

| MoS2 filled | Grey, black | Higher crystallinity |

| Heat stabilized | Blue, black | Higher cont. Temp. Use |

| Oil-filled | Natural, green, others | High load / low speed |

| Oil & MoS2 filled | Dark blue, black | Crystallinity + lubricant |

| Solid lubricant filled | Red, grey, black | Highest PV rating |

| Solid lubricant filled | Purple | Lowest “stick-slip” |

| Impact modified | Blue, yellow | High impact resistance |

There are also alloys of PA 6, such as PA 6/12, which can offer lower moisture absorption and higher impact resistance.

Again, it is nylon’s combination of properties that make it so widely used. There are many applications that have 4 or 5 key property requirements, where nylon isn’t #1 on any of them but #2 on all of them!

Too many choices? No worries – the nylon experts at WS HAMPSHIRE can guide you through the selection process. You’re in the right place!

Tom Connelly is a self proclaimed “Street Engineer” with over 40 years in the plastics industry.