Compare Sheet Only:

Compare Tube Only:

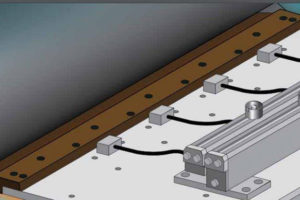

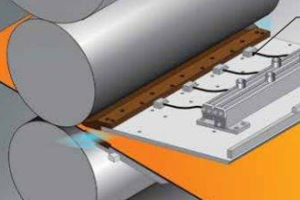

Work Roll cooling is a vital aspect of steel coil production within the Hot Strip Mill. Large volumes of water and coolant are sprayed onto the rolls so that they do not overheat, crack, and deform due to the extreme temperatures involved in the process. While water is an absolute necessity in order to preserve the quality of the work rolls, too much water on the strip will cause surface quality defects. These defects lead to downstream processing issues and imperfections that can be seen by consumers in the steel that is used for applications such as automobile bodies and appliances.

Of major concern to the operations, maintenance, and engineering teams in the Hot Strip Mill is the amount of downtime needed to change out these parts. Each part only takes 20 minutes or so to change out, and a team of two is needed. There are up to 32 such parts in the production line. Change outs are normally done on a monthly basis which means that approximately 256 man hours per year are needed to maintain these parts.

Our recommendation has been to replace the Micarta strippers/wipers that are traditionally used with Ryertex grades that have higher operating temperatures and wear at a slower rate. This means less frequent changeouts and the ability to allocate labor hours to other projects. Several mills have seen the part life DOUBLE… meaning that they gain approximately 128 man hours per year – that is almost one month!

Understanding what problems needed to be solved and the application environment have resulted in another value added win for the customer. To learn more about this project or how our materials expertise, combined with precision CNC machining services can benefit your next project, contact us today.