Compare Sheet Only:

Compare Tube Only:

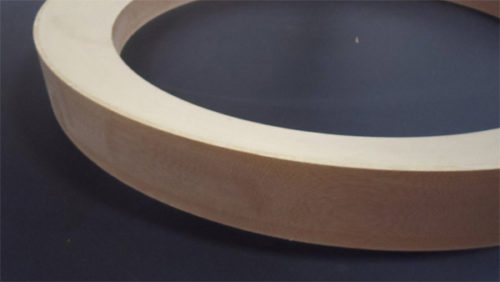

WS Hampshire, Inc.’s CNC machining and lathe turning capabilities allow us to fabricate large diameter parts with extreme precision, and we continue to lead the competition by reaching the highest possible quality standards. This part was constructed from Ryertex C to guarantee that it would have the strength and impact resistance to withstand a severe industrial environment where it is crucial for keeping harmful dust contained. Featuring dimensions of 31.490” in diameter and 2.975″ in thickness, our combination of skills and our equipment enabled us to maintain tight ± 0.005″ tolerances. Both visual and dimensional inspections verified that we met the customer’s strict specifications.

WS Hampshire, Inc.’s CNC machining and lathe turning capabilities allow us to fabricate large diameter parts with extreme precision, and we continue to lead the competition by reaching the highest possible quality standards. This part was constructed from Ryertex C to guarantee that it would have the strength and impact resistance to withstand a severe industrial environment where it is crucial for keeping harmful dust contained. Featuring dimensions of 31.490” in diameter and 2.975″ in thickness, our combination of skills and our equipment enabled us to maintain tight ± 0.005″ tolerances. Both visual and dimensional inspections verified that we met the customer’s strict specifications.

Capabilities include high speed, heavy load applications with high coefficient of friction along with high temperatures upto 400C.

If you would like more information about this project, or how our expertise for machining high-performance thermoset plastics can benefit your next applications, contact us today.