What Is an Industrial Laminate?

Leave a CommentIndustrial laminates are used in a wide range of commercial and industrial applications. WS Hampshire specializes in laminate fabrication, and our Ryertex® composite laminates and TIMCO Technical Plastics brands are known as the best in the industry. From electrical circuit boards and structural panels to bearings, bushings, and wear parts, our industrial laminates deliver reliable performance across diverse industries.

Overview of Industrial Laminates

Industrial laminates are created by stacking multiple layers of materials, typically with a decorative layer on top and a supportive substrate on the bottom. The middle layers may be fabric, paper, or glass fibers bonded together with high-quality thermosetting resins. By combining specific substrates and resins, you can produce properties that aren’t present in the individual substrates or resins alone.

The resulting sheet material is durable and features high mechanical strength, electrical insulation, machinability, and more. The materials used to create the industrial laminate vary by application and the associated demands placed upon the thermoset composite. These applications include:

- Bearings

- Electrical transformers

- Fixtures

- Gears

- Jigs

- Thermal breaks

Benefits of Industrial Laminates

Industrial laminates are trusted because of their unique and customizable characteristics. With the right combination of phenolic, melamine, silicone, or epoxy resin and substrates like canvas, paper, linen, aramid, or fiberglass, you can customize your laminate solution to fit the specific demands of the application. When aesthetics matter, the laminate can include a decorative top layer. Other benefits include:

- Durability: Industrial laminates can withstand heavy use without deforming or showing signs of wear. They’re lightweight relative to their strength.

- Chemical Resistance: Certain laminates can be safely and reliably used in environments where they’re exposed to chemicals.

- Impact Resistance: Industrial laminates are known for their impact resistance and are commonly applications such as steel rolling mills.

- Machinability: Industrial laminates are easy to work with and are easily machined to suit specific applications and environments.

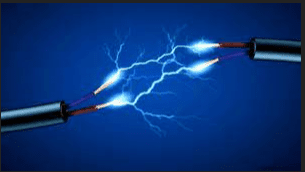

- Electrical Insulation: This prized characteristic makes industrial laminates suitable for a range of electromechanical applications.

Ryertex Industrial Laminates

Originally known as Bakelite, Ryertex is a group of phenolic thermoset laminate products that were first developed in 1907 by Leo Baekeland. Ryertex has evolved over the years and is now used in everything from electronics to heavy equipment. Traditional applications using Ryertex include buttons, frying pan handles, and telephone mouthpieces. Today, the Ryertex® family of fiber-reinforced plastic composites include a variety of substrate and resin combinations for mechanical, electrical, and heavy industrial applications like bearings, wear liners, structural components, and electrical insulation.

We also offer other phenolic composite materials, such as Arboron, Resiten, TOPLAB® PLUS, TOPLAB® BASE, TOPLAB® VERTICAL, and Virtuon® sheets.

Rely on WS Hampshire for Industrial Laminate Fabrication

As a custom fabricator of industrial laminate composites, WS Hampshire has worked with companies in a variety of industries, including paper and lumber processing, oil and gas, forestry, wire and cable, mining equipment, material handling, food and beverage packaging and processing, and more. We have global access to raw materials, and with our extensive capabilities, there is no limit to the sizes, shapes, quantities, and materials that we can produce. We’re here to help with your most complex challenges.

Contact us today to learn more about industrial laminate fabrication, or request a quote for your project.